Laser Powder Bed Fusion (LPBF) is one of the most widely used additive manufacturing processes for metals. It allows the production of highly complex and precise parts directly from digital 3D models. But how does the process actually work? In this article, we explain the main steps and what makes LPBF unique.

The process begins with a 3D CAD model of the component. This model is digitally sliced into thin layers, usually 20–60 micrometers thick. These slices are the blueprint for the laser, which will later fuse the material layer by layer.

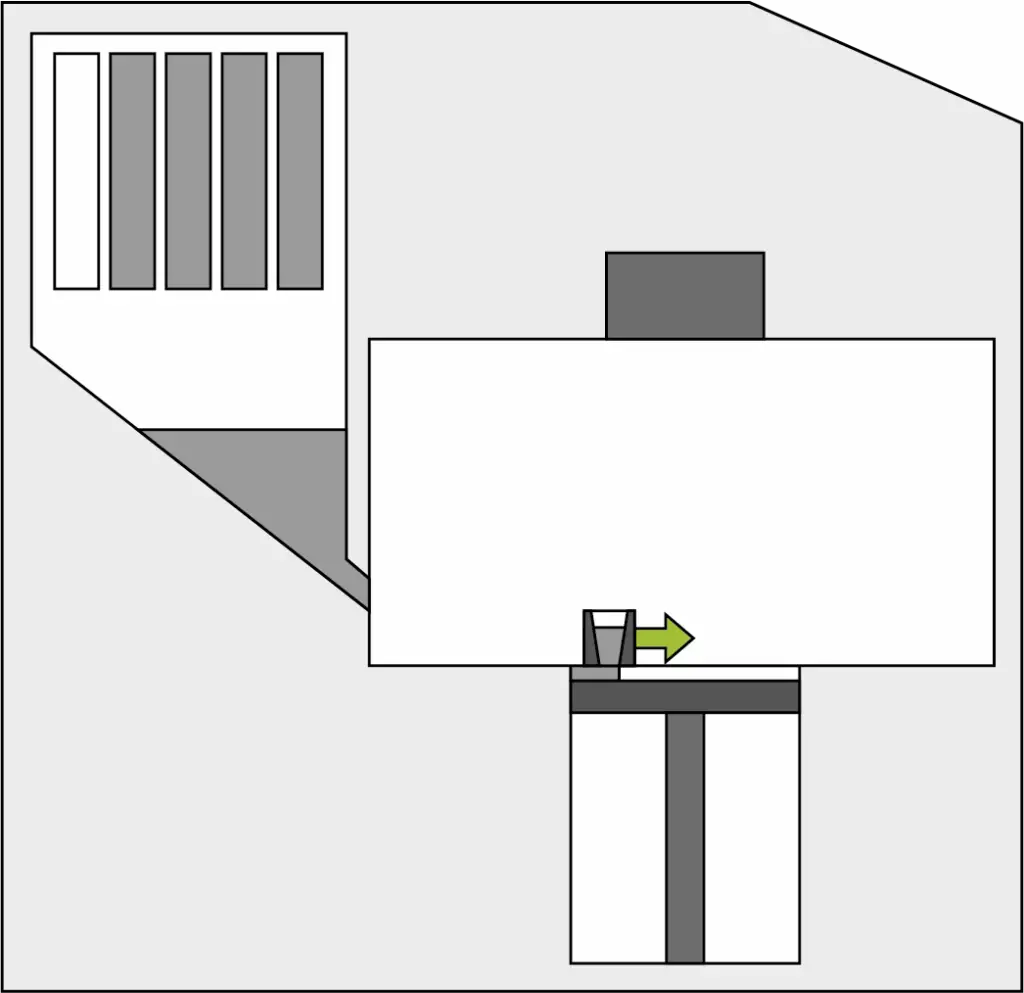

Preparing the Powder Bed

Inside the build chamber of the machine, a thin layer of metal powder is spread evenly over a build platform. The powder typically consists of fine, spherical particles of alloys such as stainless steel, titanium, aluminum, or nickel-based materials.

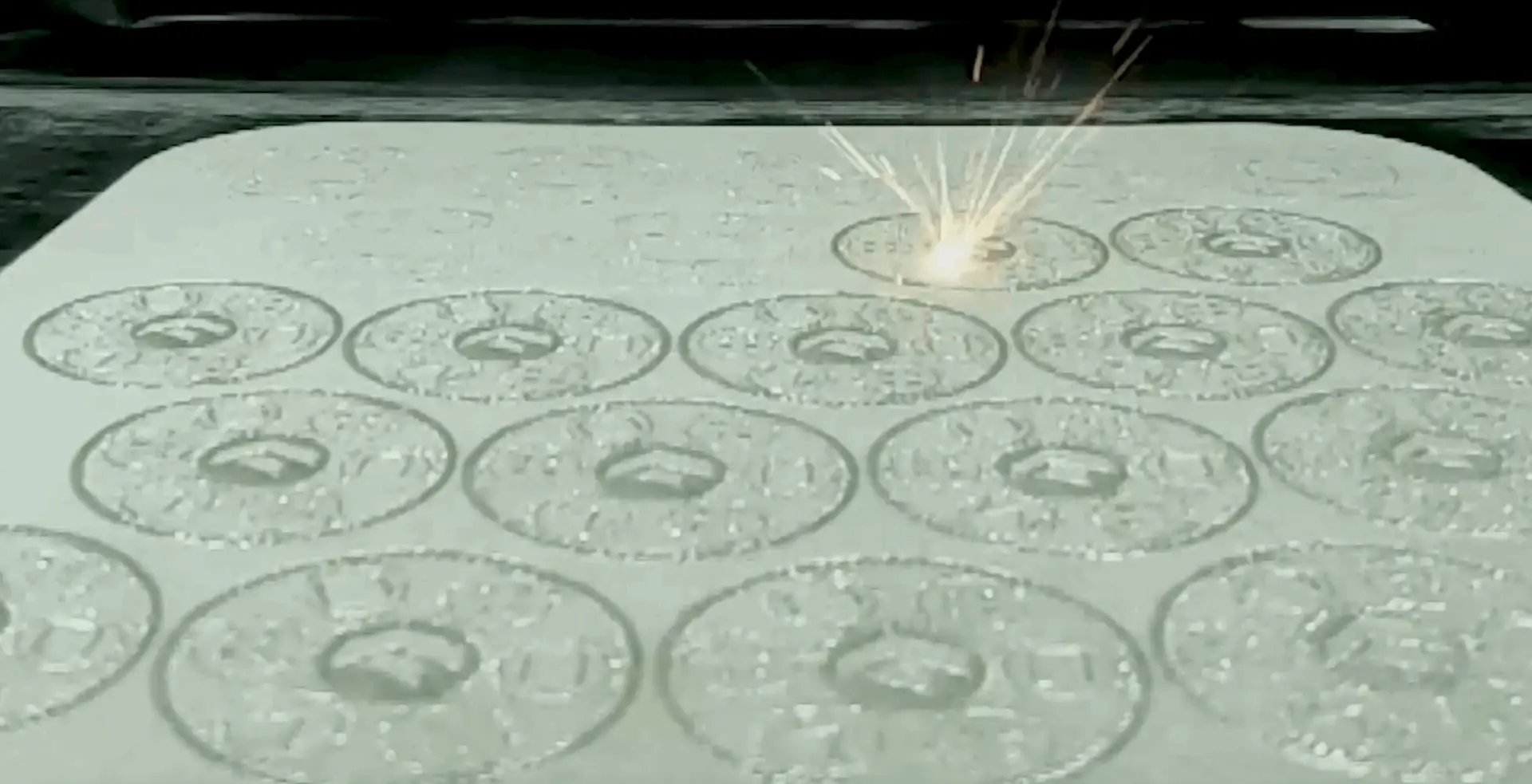

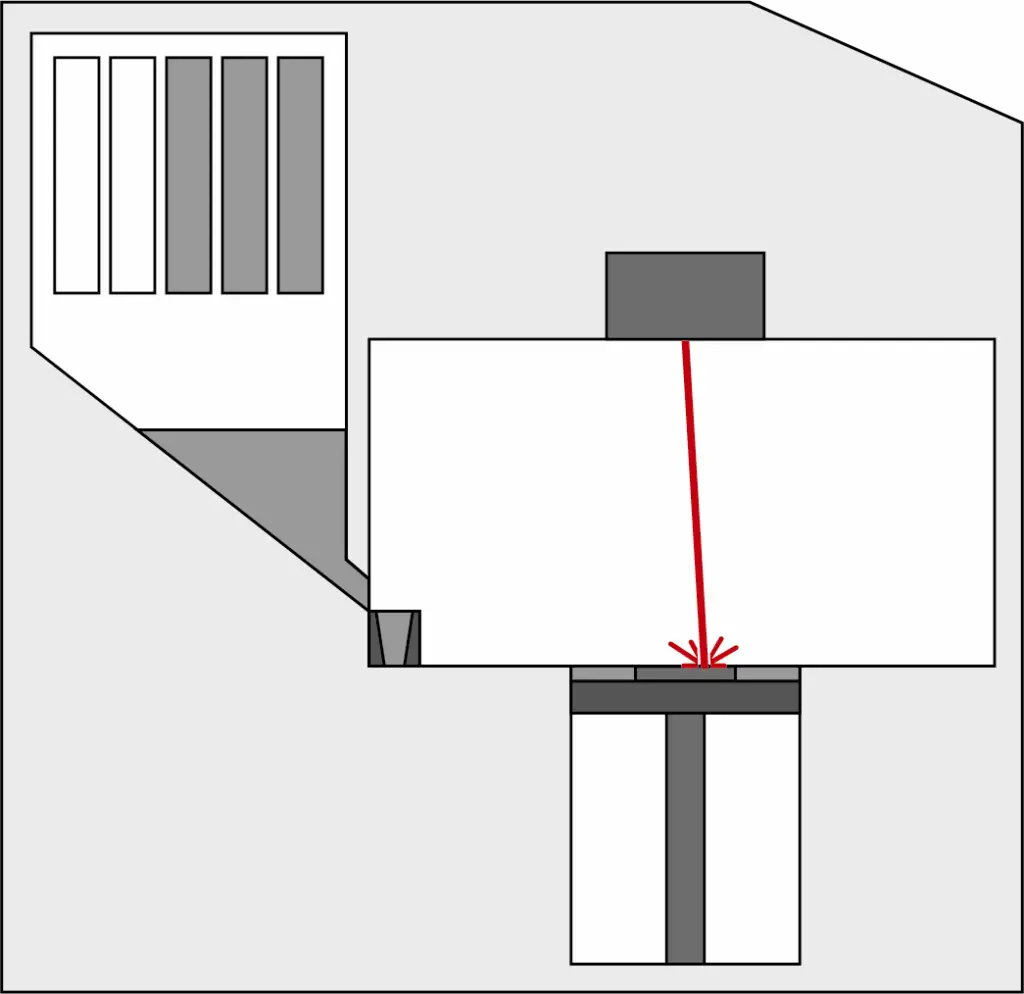

Selective Laser Melting

A high-power laser scans the cross-section of the component on the powder bed. Wherever the laser hits, the powder is locally melted and solidifies to form a dense metal structure. The laser’s precision allows very fine details and complex geometries to be produced.

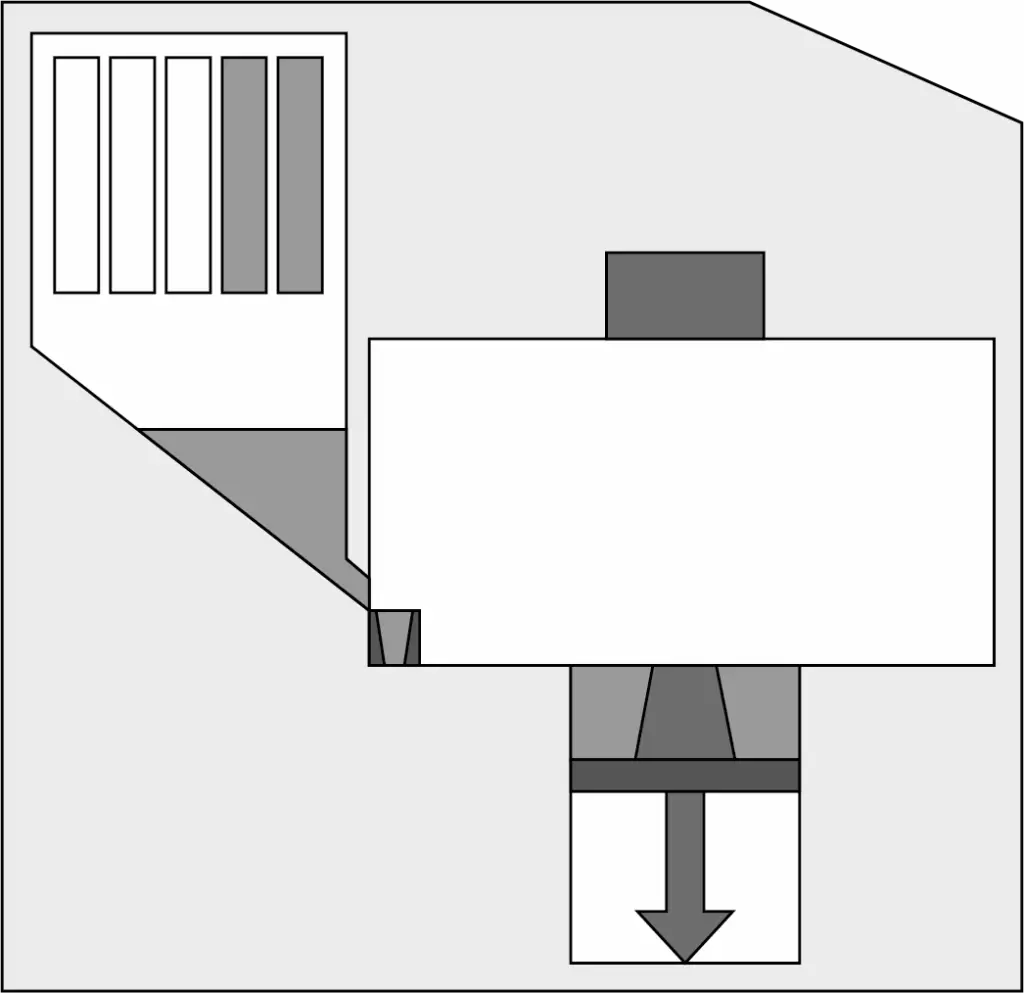

Layer-by-Layer Build-Up

Once one layer is complete, the build platform lowers slightly—by the thickness of a single layer. A recoater then spreads a fresh layer of powder across the surface, and the laser continues with the next slice of the part. This repetition of melting and layering continues until the entire component is built.

Unfused powder remains around the part during the build and supports the geometry. After the build is finished, this powder can be collected, sieved, and reused. Efficient powder management is crucial for both cost-effectiveness and safety. Our cartridge system and the automated sieving station enable both.

Advantages of LPBF

-

High design freedom: Complex geometries, lattices, and internal channels are possible.

-

Material efficiency: Most unused powder can be recycled.

-

Excellent precision: Fine structures and thin walls can be produced.

-

Strong mechanical properties: Parts are fully dense and comparable to conventionally manufactured components.

LPBF is a powerful additive manufacturing process that enables the production of advanced metal parts with high precision and design freedom. By building layer by layer from digital data, manufacturers can move from idea to functional part faster and with less material waste.

Explore our powerful metal 3d printers and its unique features on our product page.