Knife manufacturing places high demands on material performance, precision, and design quality. Metal 3D printing for knife manufacturing enables producers to develop high-performance blades and handles with greater design freedom, near-net-shape accuracy, and advanced material properties. Using Laser Powder Bed Fusion (LPBF), knife makers can manufacture functional prototypes and serial components from high-performance metals, achieving sharper edges, improved durability, and highly differentiated designs.

This article explores how metal 3D printing is transforming knife manufacturing – from prototyping to production.

Rapid Prototyping and Functional Knife Designs

One of the key advantages of LPBF is the ability to produce fully functional prototypes without tooling or molds. Knife manufacturers can quickly test blade and handle geometries using real metal parts rather than plastic models or simulations.

Because design changes can be implemented directly in the CAD model, iterations can be produced rapidly. This significantly shortens development cycles and allows knife makers to refine ergonomics, balance, and performance early in the process – all with production-relevant materials.

High-Performance Materials for Maximum Demands

LPBF enables the processing of hardenable steels and advanced alloys that are ideal for knife applications. Due to rapid solidification during the printing process, LPBF produces a fine microstructure, resulting in improved edge stability and reduced microchipping compared to conventionally manufactured steels.

Typical materials used in metal 3D printed knives include:

- 1.2709 / M300 tool steel – hardenable up to 58 HRC, ideal for blades

- Cxplus corrosion-resistant tool steel – hardenable up to 56 HRC, optimized for blades

- Titanium Grade 23 – lightweight, excellent strength-to-weight ratio, ideal for handles and accessories

- 17-4PH stainless steel – suitable for blades and functional components

- A6061-RAM2 aluminum – lightweight and anodizable, ideal for handles and accessories

This material flexibility allows manufacturers to tailor each knife component precisely to its functional requirements

Near-Net-Shape Manufacturing and Design Freedom

Metal 3D printing enables near-net-shape manufacturing, meaning blades and handles can be produced very close to their final geometry. This significantly reduces grinding, machining, and post-processing effort, saving time and cost.

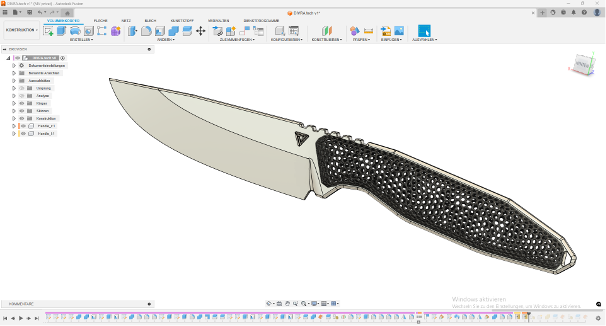

At the same time, LPBF offers virtually unlimited design freedom. Complex blade geometries, lattice-reinforced handles, internal cavities, and brand-specific contours can be integrated directly into the part geometry. Logos, textures, and functional surfaces become part of the design rather than secondary operations.

Designs that would be impossible or prohibitively expensive with conventional manufacturing can be realized efficiently using metal 3D printing

Functional Integration and Added Value

Beyond shape freedom, LPBF allows multiple functions to be integrated into a single component. Knife designs can include features such as:

- Bottle openers

- Screwdrivers or hex wrenches

- Cutting hooks

- Internal compartments for lightweighting or storage

By reducing assembly steps and combining functions into monolithic parts, manufacturers can improve robustness while delivering unique, multifunctional products that stand out in the market.

Sustainability and Manufacturing Efficiency

Metal 3D printing supports a more resource-efficient and sustainable manufacturing approach. LPBF uses only the material required for the part, and unused powder can be fully recycled.

With minimal waste, reduced machining, and lower energy consumption compared to traditional manufacturing, metal 3D printing enables responsible production. Combined with on-demand manufacturing, it reduces inventory, overproduction, and storage requirements – an increasingly important factor for modern knife manufacturers.

Proven in Practice: Knife Manufacturers Using Metal 3D Printing

Metal 3D printing is already being used successfully in real-world knife production. Manufacturers such as Midgards Knives and Divra are producing high-quality knives on metal 3D printing systems from One Click Metal.

These customer applications demonstrate how precision, reliability, and performance in metal additive manufacturing can be translated directly into craftsmanship and product quality.

Conclusion: Metal 3D Printing for Knive Manufacturing

Metal 3D printing is redefining what is possible in knife manufacturing. By enabling rapid prototyping, near-net-shape production, advanced material performance, and unprecedented design freedom, LPBF gives knife makers powerful tools to innovate and differentiate.

For manufacturers looking to combine performance, aesthetics, and efficiency, metal 3D printing offers a future-ready approach to producing knives that stand out both technically and visually.