Point Designs, a prosthetics manufacturer specializing in heavy-duty finger prostheses, uses in-house metal 3D printing to serially produce high-precision titanium components. By implementing metal additive manufacturing on their own premises, the company eliminated dependency on external suppliers and unlocked faster iteration cycles, lower costs, and improved control over innovation and intellectual property.

About Point Designs: Engineering Prosthetics for Real-World Use

Founded in 2016 by researchers from the Biomechatronics Development Laboratory at the University of Colorado, Point Designs specializes in high-performance, patient-specific finger prostheses for individuals with partial hand loss.

With more than 45,000 finger amputations occurring annually in the United States, the demand for durable, lightweight, and functional prosthetic solutions is significant. Point Designs combines mechanical engineering, additive manufacturing expertise, and clinical insight to restore independence and functionality for prosthetic users.

The Challenge: Scaling Production While Maintaining Control

At the core of Point Designs’ prosthetic systems are heavy-duty titanium finger components. These parts are exposed to constant mechanical stress and must perform reliably during daily use, all while remaining lightweight and precisely engineered.

In the early stages, Point Designs relied on external manufacturing partners to produce these complex titanium components. While this approach enabled a fast market entry, it became increasingly restrictive as the company grew.

Key challenges included:

- High production costs, particularly for small batches and frequent design iterations

- Long and unpredictable lead times, slowing down development cycles

- Limited design flexibility, making rapid testing and optimization difficult

- Reduced control over intellectual property and quality, especially for sensitive designs

With an annual demand of approximately 1,500 finger components, outsourcing was no longer a sustainable solution.

The Application: Titanium Fingers for Heavy-Duty Prosthetic Systems

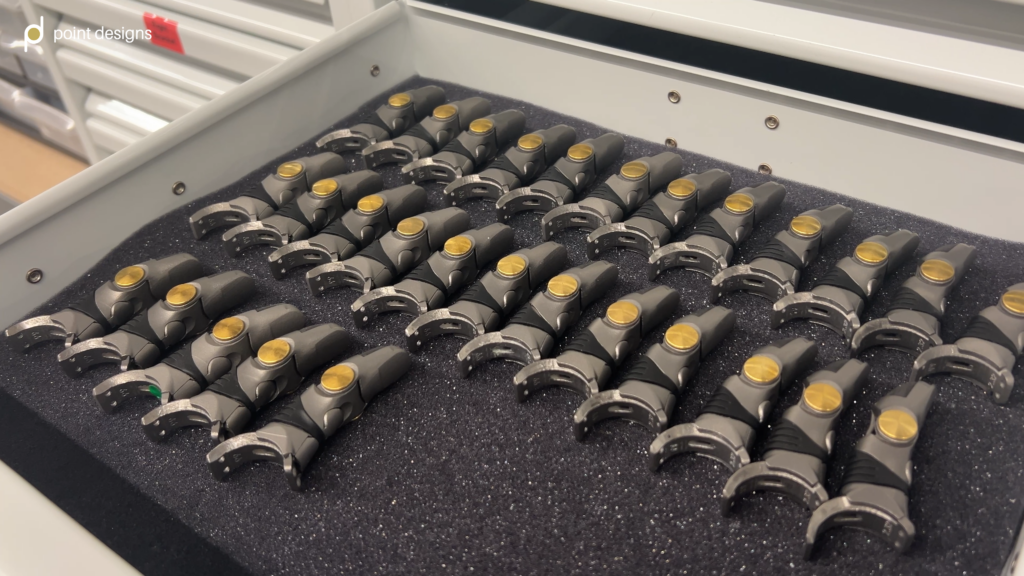

The titanium finger components are the main structural and functional elements of the prosthetic system. They enable smooth articulation, a robust locking mechanism, and long-term durability.

To meet medical and functional requirements, each component must offer:

- High mechanical strength

- Low weight for user comfort

- Precision for reliable motion and fit

- Consistent quality suitable for serial production

Achieving this combination efficiently was a key driver for bringing production in-house.

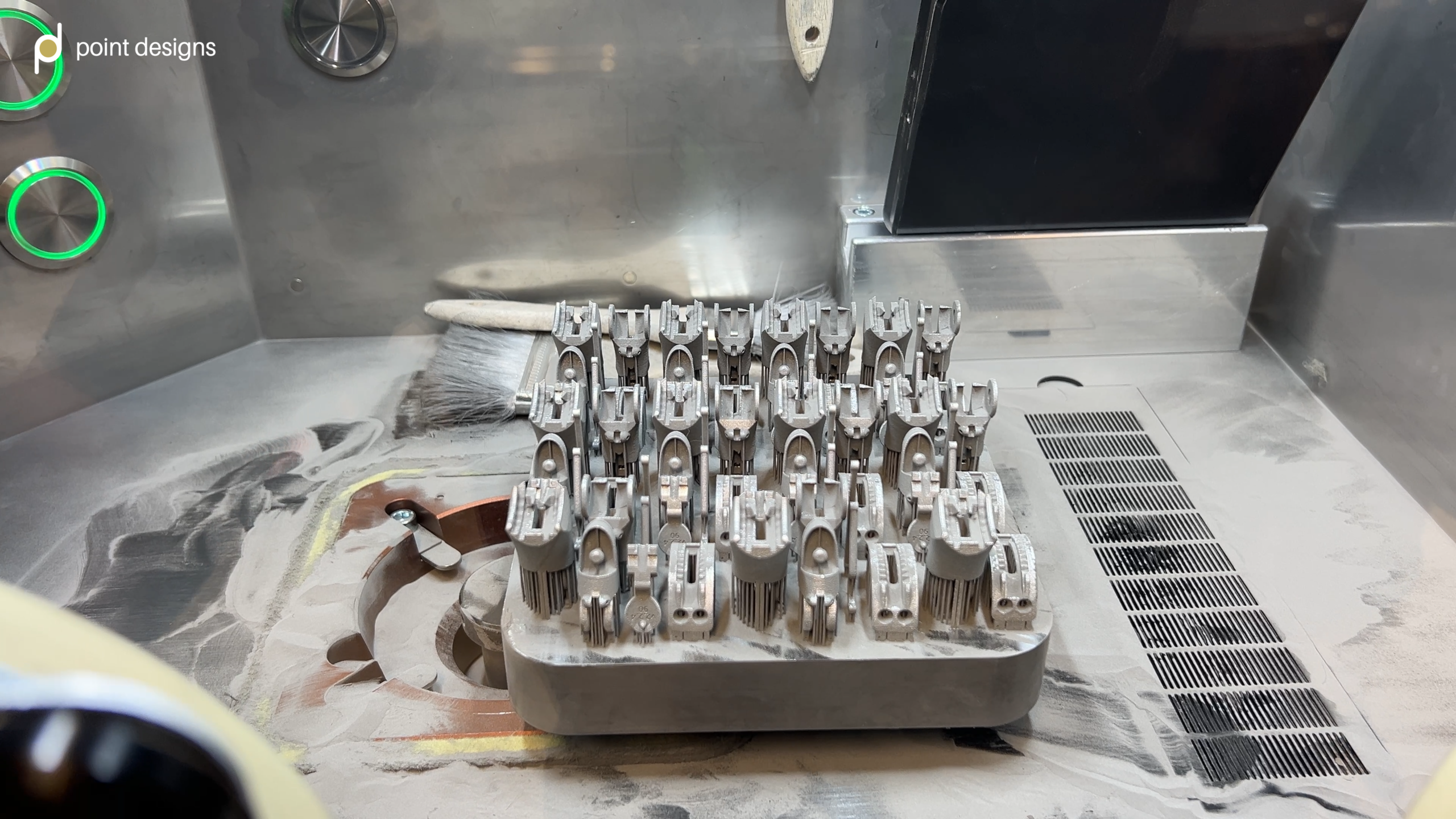

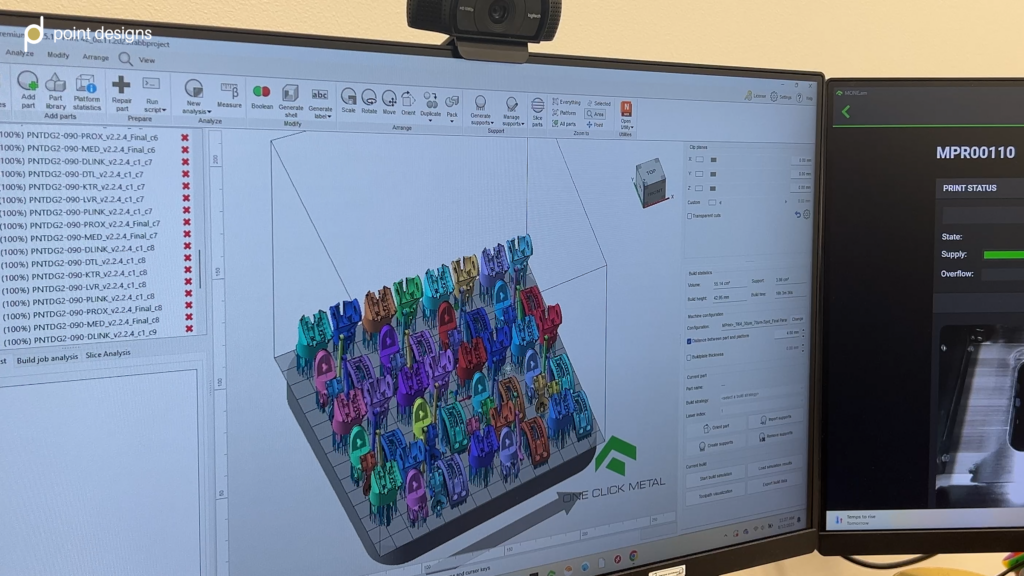

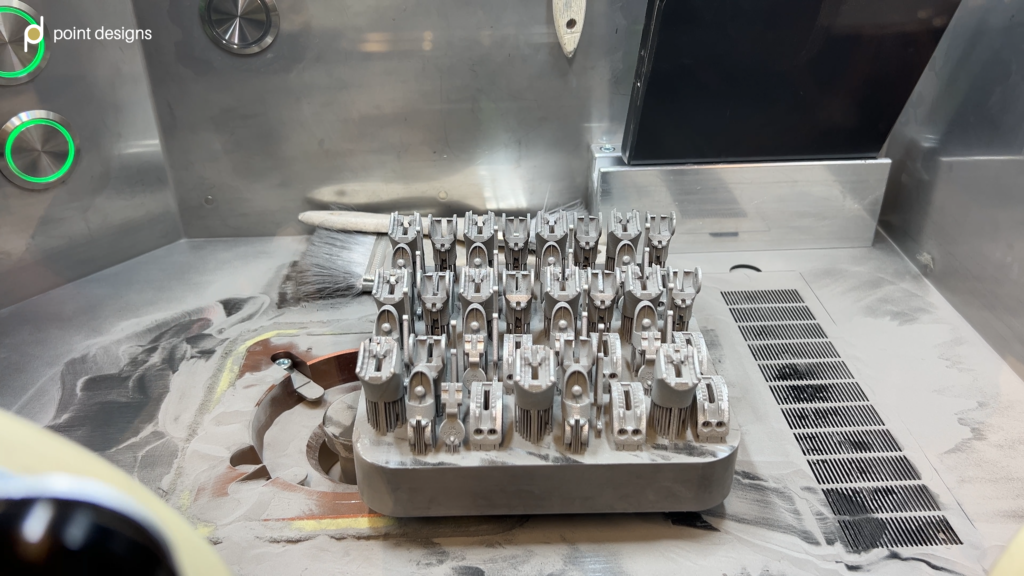

To overcome these challenges, Point Designs invested in a BASEline metal 3D printing system from One Click Metal, using Laser Powder Bed Fusion (LPBF) technology.

The Solution: In-House Metal 3D Printing with One Click Metal

This decision enabled the company to manufacture titanium finger components directly from finalized CAD data on its own premises without relying on external suppliers. Optimized part orientation and intelligent design keep support structures to a minimum, reducing post-processing effort and accelerating assembly.

A single build can produce 74 finger components (11 assemblies) in just 16 hours, enabling efficient batch production and consistent quality. The resulting components are lightweight, mechanically robust, and precisely engineered – well suited for daily medical use.

Why Point Designs Chose One Click Metal

Several factors made One Click Metal the right choice for Point Designs:

- Cost-efficient metal AM system designed for small and medium-sized businesses

- Compact footprint, ideal for limited production space

- Minimal infrastructure requirements, enabling fast integration

- Excellent return on investment, especially for small, high-value titanium parts

The build plate size matched the component dimensions perfectly, allowing Point Designs to scale production without unnecessary complexity.

The Results: Measurable Improvements Across the Value Chain

By moving from outsourced manufacturing to in-house metal 3D printing, Point Designs achieved clear and measurable benefits:

- 50% faster lead times, reducing delivery from weeks to days

- Significant cost reduction by eliminating third-party manufacturing and logistics

- Greater design flexibility, enabling rapid iteration and continuous optimization

- Full control over intellectual property and quality, strengthening innovation and data security

Most importantly, faster production translates directly into quicker delivery of prosthetic devices – improving outcomes for patients.