In applications where extreme temperatures, mechanical loads, and corrosive environments come together, conventional materials quickly reach their limits. This is where nickel-based superalloys come into play.

Inconel metal 3D printing, specifically with Alloy 718 (2.4668), enables the production of highly durable components that retain their mechanical properties under extreme operating conditions. Combined with Laser Powder Bed Fusion (LPBF), Alloy 718 allows manufacturers to produce complex, high-performance parts that would be difficult or impossible to manufacture using traditional methods.

What Is Alloy 718 (Inconel 718)?

Alloy 718 (material number 2.4668) is a nickel-based superalloy known for its exceptional strength, corrosion resistance, and stability at elevated temperatures. The alloy contains significant amounts of chromium and molybdenum, which provide excellent oxidation and corrosion resistance, even in aggressive environments.

Another key advantage is that Alloy 718 is heat treatable, allowing its mechanical properties to be tailored to specific application requirements.

Key material characteristics include:

- High strength and toughness

- Excellent corrosion and oxidation resistance

- Good creep resistance

- Stable mechanical performance at high temperatures

- Good processability in LPBF

These properties make Alloy 718 a preferred material for safety-critical and high-load applications

Typical Applications of 3D Printed Inconel

Due to its unique property profile, Inconel Alloy 718 is widely used in industries where failure is not an option.

Typical application areas include:

- Aviation, aerospace and defense, such as turbine components and structural parts

- Energy industry, including gas turbines and high-temperature components

- Automotive, for high-performance and motorsport applications

- Casting industry, for tools exposed to thermal cycling

Metal 3D printing enables the production of complex internal geometries, cooling channels, and lightweight structures that further enhance component performance.

Mechanical Performance at Elevated Temperatures

In the annealed condition, Alloy 718 already offers excellent mechanical properties, with a tensile strength of approximately 1030 N/mm². After appropriate heat treatment, tensile strength can increase to up to 1450 N/mm², making the alloy suitable for extreme mechanical loads.

Key performance characteristics include:

- High creep rupture strength

- Retention of mechanical properties from cryogenic temperatures up to 700 °C

- Oxidation resistance up to 1000 °C

These properties make Inconel Alloy 718 a reliable choice for components exposed to long-term thermal and mechanical stress

Surface Quality and Part Integrity

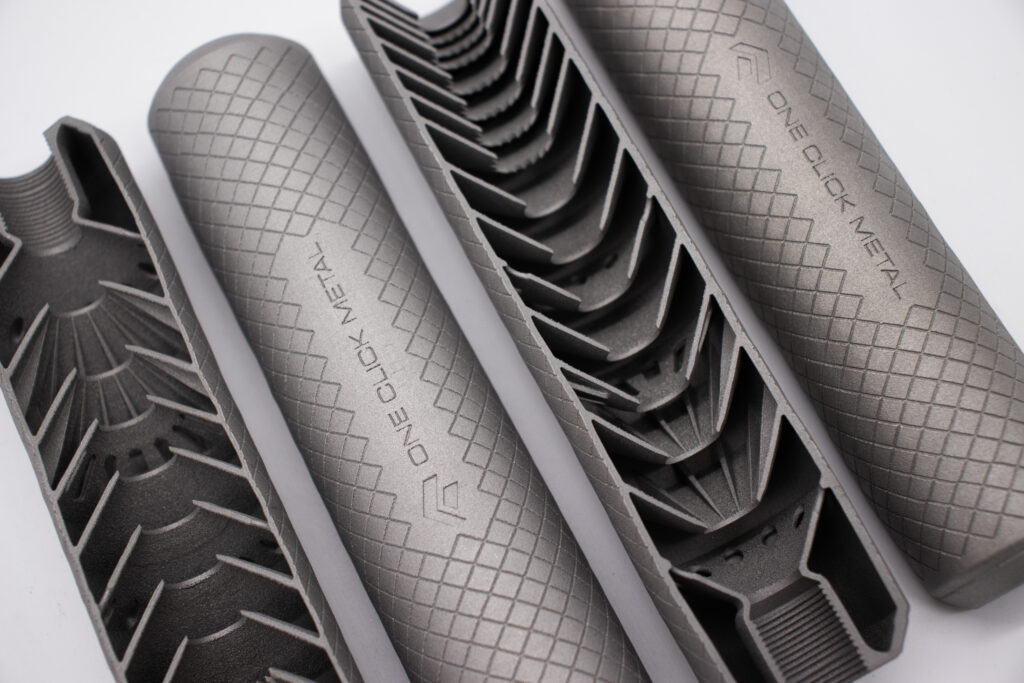

LPBF-printed Alloy 718 components show excellent part integrity and surface quality.

- Average internal defect rate: < 0.1%

- As-built surface roughness (Ra): ~3 µm

- After blasting (Ra): ~2 µm

This high level of process stability ensures reliable performance, even for complex geometries and thin-walled structures

Why Inconel and Metal 3D Printing Are a Powerful Combination

Nickel-based superalloys fully benefit from the strengths of metal additive manufacturing:

- Complex internal geometries improve thermal and mechanical performance

- Material is used only where needed, reducing waste

- High-value components can be produced efficiently in small to medium volumes

- Design iterations can be implemented quickly without tooling

For manufacturers operating in extreme environments, Inconel metal 3D printing provides a unique combination of performance, flexibility, and efficiency.

Conclusion: Alloy 718 as a Benchmark Material for Extreme Applications

Inconel Alloy 718 sets the benchmark for metal 3D printing applications exposed to heat, pressure, and corrosion. Its outstanding mechanical performance, combined with LPBF design freedom, enables the production of components that meet the highest industrial demands.