Lerdsin Hospital, a leading public teaching hospital in Bangkok, Thailand, is transforming orthopedic care through the use of patient-specific metal 3D printed implants. By integrating metal additive manufacturing directly into its clinical workflow, the hospital enables customized solutions for complex cases that cannot be addressed with standard, off-the-shelf implants.

This case study demonstrates how metal 3D printing can support surgeons in treating severe bone deformities with greater precision, efficiency, and improved patient outcomes.

About Lerdsin Hospital: A Leader in Orthopedic Care

Founded in 1889, Lerdsin Hospital is one of Thailand’s most established public hospitals. With over 500 beds, it serves a high volume of patients annually and plays a vital role in urban healthcare. The hospital is particularly recognized for its Orthopedics Department, which has been active since 1957 and functions as an accredited training center.

As a teaching hospital affiliated with the Ministry of Public Health and several universities, Lerdsin Hospital is committed to advancing medical innovation while providing high-quality, affordable healthcare. The integration of metal 3D printing reflects a broader vision: making personalized orthopedic treatment accessible to more patients across Thailand.

The Challenge: When Standard Implants Are Not an Option

One orthopedic patient at Lerdsin Hospital presented with a severe bone malunion, where a fracture had healed in a distorted position. The resulting bone geometry was highly irregular, making reconstruction extremely challenging.

Standard titanium locking plates available on the market could not conform to the patient’s bone surface. Using these implants would have left gaps between the plate and the bone, compromising stability and significantly increasing the risk of implant failure.

In addition to the complex anatomy, the surgical team faced strict requirements:

- Maximum surface contact between implant and bone

- Proven biocompatibility for long-term implantation

- High mechanical strength to withstand daily loads

- Precisely defined screw hole orientation for accurate fixation

Meeting all these conditions with conventional manufacturing methods was virtually impossible

The Requirements for a Successful Implant

To ensure a successful surgery and long-term outcome, the implant plate needed to meet several critical criteria:

- Biocompatibility: Medical-grade titanium to ensure safe integration with human tissue

- Mechanical strength: Durability under daily movement and load-bearing

- Precise screw hole orientation: Accurate alignment based on the patient’s anatomy

- Maximized surface contact: A perfect fit against the bone to promote stability and healing

Only a fully customized solution could fulfill all these requirements simultaneously.

The Solution: Patient-Specific Metal 3D Printed Implant

Lerdsin Hospital addressed the challenge by utilizing its metal 3D printing system from One Click Metal. This enabled the team to move from diagnosis to a patient-specific solution within a short timeframe.

The process began with creating a high-resolution 3D model of the patient’s bone from medical imaging data. Based on this model, the surgical team designed customized cutting and reduction guides using Materialise software, allowing the operation to be planned and executed with high precision.

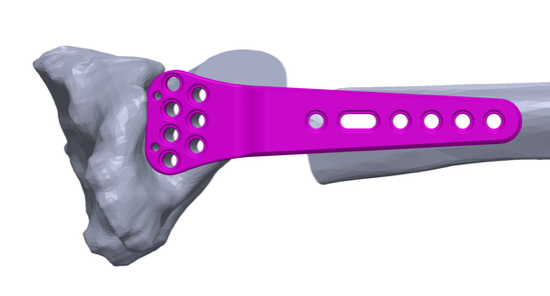

Once the bone was repositioned, its anatomy changed significantly in both alignment and rotation. A conventional implant would no longer fit. To solve this, a fully customized titanium implant plate was designed and 3D printed to match the post-reduction bone geometry exactly.

The result was an implant with:

- Maximized surface contact

- Correct screw hole orientation

- Mechanical strength to support healing

By integrating metal 3D printing directly into the surgical workflow, the team achieved a stable fixation that would not have been possible with standard implants.

Clinical and Technical Expertise Behind the Project

The success of the case was driven by close collaboration between surgeons and engineers:

- Dr. Navapong Anantavorasakul, MD, Orthopedic Surgeon specialized in hand and microsurgery, guided the clinical strategy and defined surgical requirements.

- Napakarn Thussakorn, Biomedical Engineer, translated clinical needs into 3D printed solutions – from converting CT scans into models to designing guides, instruments, and implants.

As Dr. Navapong explains:

“We want to offer patients the opportunity to receive modern, personalized treatment using 3D printing technology.”

The Advantages of Patient-Specific Metal Implants

The use of metal 3D printing delivered clear benefits for both surgeons and patients:

- Increased surgical precision through implants and guides tailored to the patient’s anatomy

- Easier operation planning, with every step defined in advance

- Shorter operation times, reducing anesthesia risks and improving efficiency

- Reduced overall treatment costs, often saving around €1,000 compared to commercial implants

- Full customization, enabling stable fixation even in severely deformed bones

Once the patient’s bone is scanned, design and manufacturing can be completed within days, enabling rapid clinical response.

Technical Overview

- Component: Patient-specific orthopedic implant plate

- Material: Titanium

- Technology: LPBF with 200 W fiber laser

- Layer height: 20 µm

- Build time: 1 hour 36 minutes

- Printing costs: approx. €49

Conclusion: Advancing Orthopedic Care with Metal 3D Printing

This case highlights the transformative potential of patient-specific metal 3D printing in orthopedic surgery. By producing customized titanium implants in-house, Lerdsin Hospital enables treatments that are more precise, efficient, and cost-effective – especially for complex cases where standard solutions fail.

By combining clinical expertise with metal additive manufacturing technology, Lerdsin Hospital is setting new standards for personalized orthopedic care and demonstrating how metal 3D printing can directly improve patient outcomes.