In addition to implants and prosthetics, metal 3D printing is changing the way medical tools and surgical instruments are designed and manufactured. Hospitals, research institutions, and medical device companies increasingly rely on additive manufacturing to produce precise, durable, and customizable tools that support modern surgical procedures.

With demand growing for specialized medical equipment, additive manufacturing is emerging as a critical enabler of innovation: from prototyping new instruments to serial production of complex tools.

Why Metal 3D Printing Is Ideal for Medical Tools

1. Precision and Design Freedom

Metal 3D printing allows highly complex internal and external geometries that cannot be produced using conventional machining. Surgical tools benefit from:

- integrated channels

- ergonomic shapes

- lightweight structures

- optimized cutting edges

This enhances both surgical efficiency and instrument handling.

2. Rapid Prototyping and Faster Innovation

Hospitals such as Lerdsin Hospital in Bangkok use metal AM to prototype surgical instruments quickly, enabling faster iteration and reduced development costs.

3. Customizable and Patient-Specific Tools

Additive manufacturing supports the creation of custom surgical guides and tools tailored to the patient – especially useful in orthopedic or maxillofacial surgery.

4. Durable, Biocompatible Materials

Stainless steel (316L / 1.4404) and titanium (Ti6Al4V) offer:

- high strength

- corrosion resistance

- biocompatibility

- long product life

making them ideal for reusable medical instruments.

Examples of 3D-Printed Medical Tools from the Field

Curved Surgical Chisel – High Precision for Orthopedic Procedures

Customer: Lerdsin Hospital, Bangkok (Thailand)

Material: Ti6Al4V

Application: Orthopedic bone cutting and shaping

This curved chisel is used in orthopedic surgery to cut, shape, or remove bone with high precision. Thanks to metal 3D printing, surgeons benefit from ergonomic, lightweight designs that improve handling during complex procedures.

Triple Drill Sleeve – Precision Guidance for Orthopedic Fixation

Customer: Lerdsin Hospital, Bangkok (Thailand)

Material: Ti6Al4V

Application: Guiding drill accuracy during bone fixation

The triple drill sleeve ensures highly accurate alignment when drilling into bone: a crucial factor when placing screws for fixation systems. Metal AM enables fine internal channels and geometries that would be extremely difficult to machine.

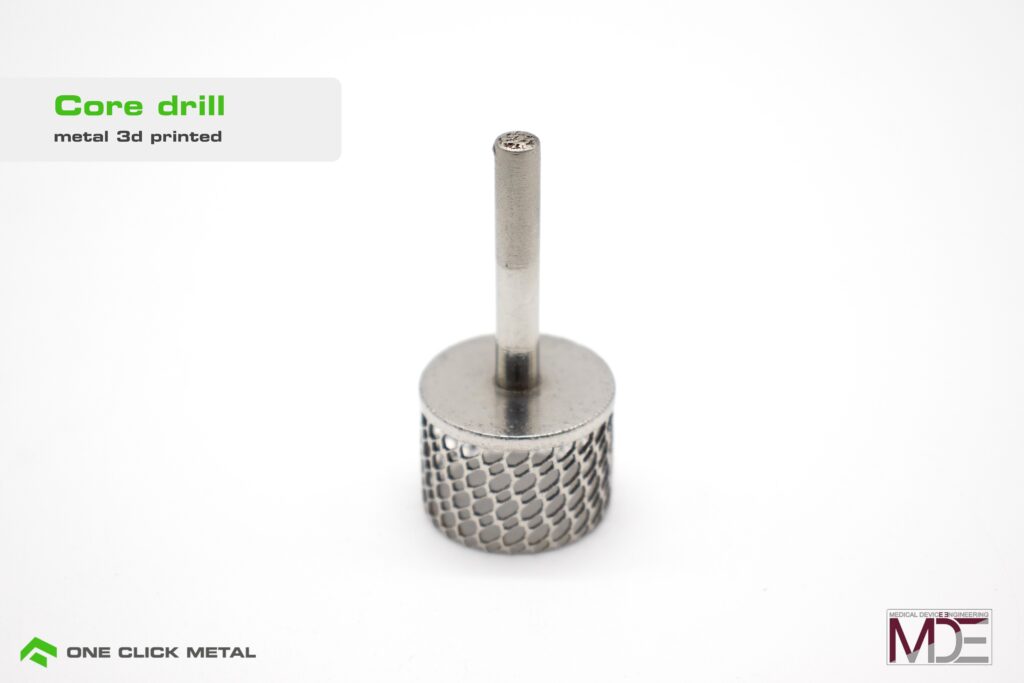

Core Drill – Advanced Tool for Tissue Sampling

Customer: MDE, Villa Carcina (Italy)

Material: 316L stainless steel

Print Time: 6 hours per part

The core drill is widely used for tissue sampling, allowing cylindrical specimens to be removed for histological examination. MDE chose metal 3D printing because the tool’s complex cutting edges and internal geometry are difficult, or impossible, to achieve using conventional machining.

Conclusion: Metal AM Enables a New Generation of Surgical Tools

Metal 3D printing is reshaping how surgical instruments and medical tools are developed and manufactured. Compared to traditional methods, additive manufacturing offers:

- faster development cycles

- greater design freedom

- ability to produce highly precise and customized tools

- reduced manufacturing costs and material waste

- durable titanium and stainless-steel solutions

From curved chisels and drill sleeves to advanced core drills, hospitals and manufacturers are already using metal AM to innovate surgical tools and improve patient care.

As accessible systems like the One Click Metal ones continue to lower the entry barrier, more medical institutions will be able to design and produce their own next-generation surgical instruments.