Materials

Stainless Steel

1.4404 / 316L

The material 1.4404/316L is one of the most frequently used corrosion- resistant stainless steels. Due to the addition of molybdenum, this material offers signifi cantly improved corrosion resistance than other stainless steels. Thanks to its lower carbon content, 1.4404 is also characterized by good processing properties. Because of its properties, 1.4404 has a wide range of applications in numerous industries such as automotive, construction, aerospace, mechanical engineering and pharmaceuticals.

Properties

- Good corrosion resistance

- High tensile strength

- Good strength and rigidity

Applications

- Watches, jewellery, functional components for electronic housings and accessories

- Food and chemical facilities

- Non-corrosive components in the automotive industry

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Stainless Steel

1.4542 / 17-4PH

The material 1.4542/17-4 PH is a corrosion resistant high strength stainless steel. The presence of copper as alloying element facilitates the material to be hardened by heat treatment and age hardening methods. Due to the presence of Niobium in combination with reduced carbon content, the material is highly processable without compromising in hardness. The superior physical and chemical property of the material makes it an excellent choice for numerous applications.

Properties

- High strength and toughness

- Good corrosion resistance

- Good processability

- Magnetic

Applications

- Aviation and aerospace

- Medical components

- Food and chemical industry

- Energy industry

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Tool Steel

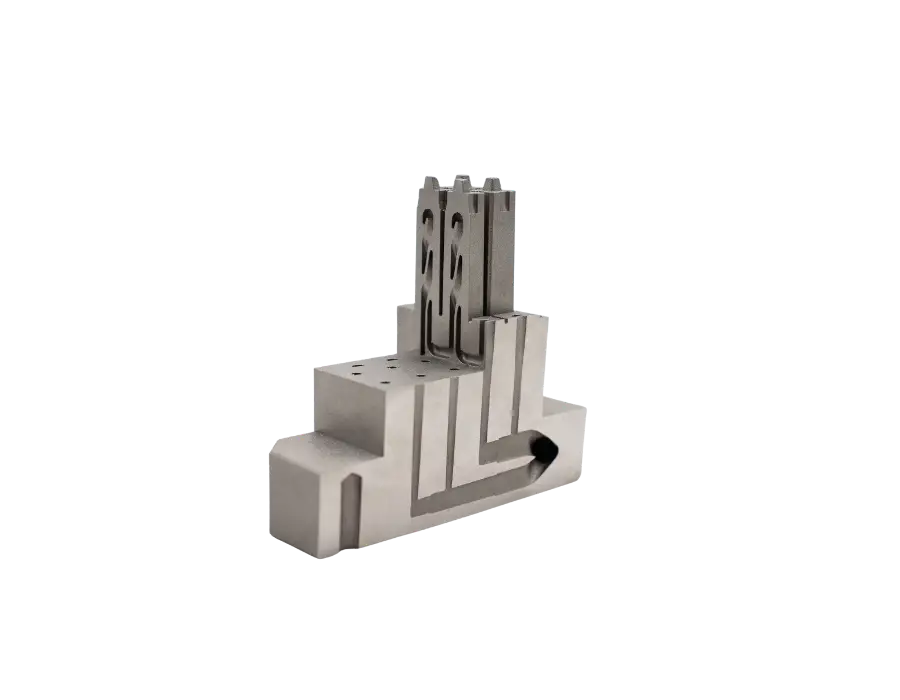

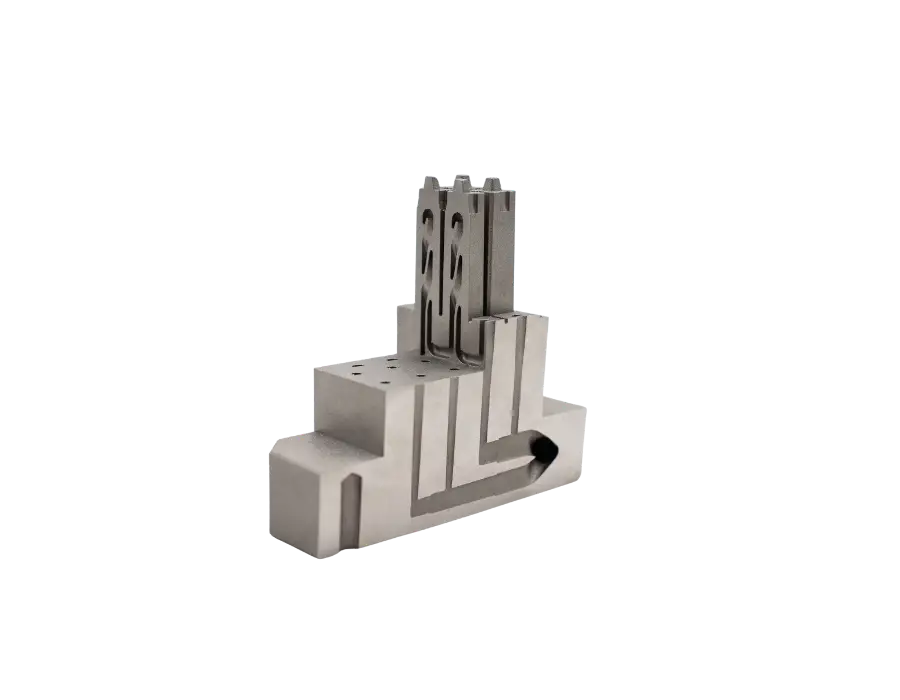

1.2709 / M300

Tool steel 1.2709/M300 is versatile and is characterised by high elongation and yield strengths. This makes 1.2709/M300 particularly suitable for the production of tool inserts and innovative mould constructions with integrated near-contour cooling for injection moulding and die casting technology. Components made from tool steel 1.2709/M300 can be easily machined after completion as well as hardened. Even after the hardening process, the components can be mechanically reworked, welded, blasted, polished or coated. The material 1.2709/M300 is used in various industries such as aerospace, automotive, prototyping, toolmaking, series production and other industrial applications that place high demands on the component. on the component.

Properties

- Thermally hardenable up to approx. 54 HRC

- Good thermal conductivity compared to other steels

Applications

- Injection moulding tools and their applications

- Pressure die-casting tool applications

- Functional prototypes, small series production, individualized products and spare parts

- Components that require particularly high strength and/or rigidity

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Tool Steel

Cxplus

Cxplus is a corrosion-resistant, maraging (martensitic aging) steel that combines the excellent processability and low cracking tendency of maraging steels in the LPBF process with outstanding strength and good corrosion resistance. The already high mechanical properties in the as-built condition can be further enhanced through aging, turning the material into a high-performance alloy with exceptional mechanical characteristics reaching hardness levels of up to 54 HRC. Thanks to its superior all-round property profile, Cxplus is the material of choice for demanding industries such as aerospace, motorsport, defense, oil & gas, and tool and mold making.

Properties

- Great strength

- Good corrosion resistance

Good mechanical properties

Applications

- Tooling and die

- Automotive parts

- Machine parts

Defense applications

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

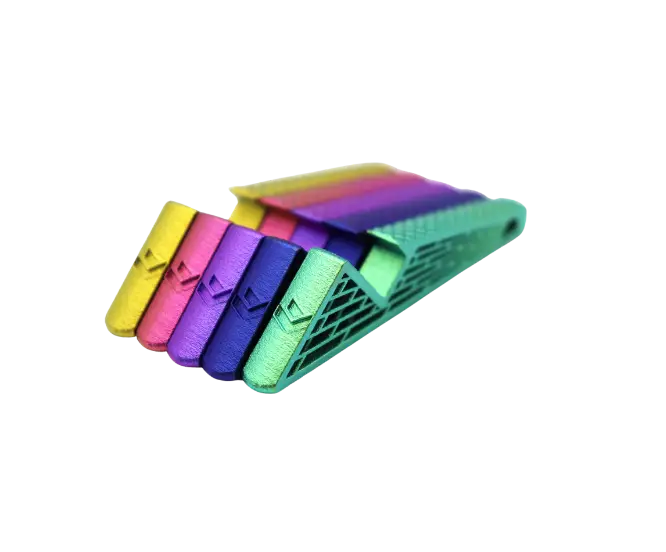

Titanium

3.7165 / Ti6AL4V grade 23

The material Ti-6Al-4V grade 23, is a light weight, high strength, corrosion resistant Titanium alloy. The presence of Al and V keeps this microstructure of the alloy stable at both lower and higher temperatures. The reduced presence of oxygen content in the grade 23 alloy improves the corrosion resistance of the alloy. Apart from having an industrial application due to the high weight to strength ratio, this alloy is also bio compatible making it an important alloy in the medical field.

Properties

- Excellent strength to weight ratio

- High fracture toughness

- High corrosion resistance

Applications

- Industrial components

- Racing industry

- Aerospace industry

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

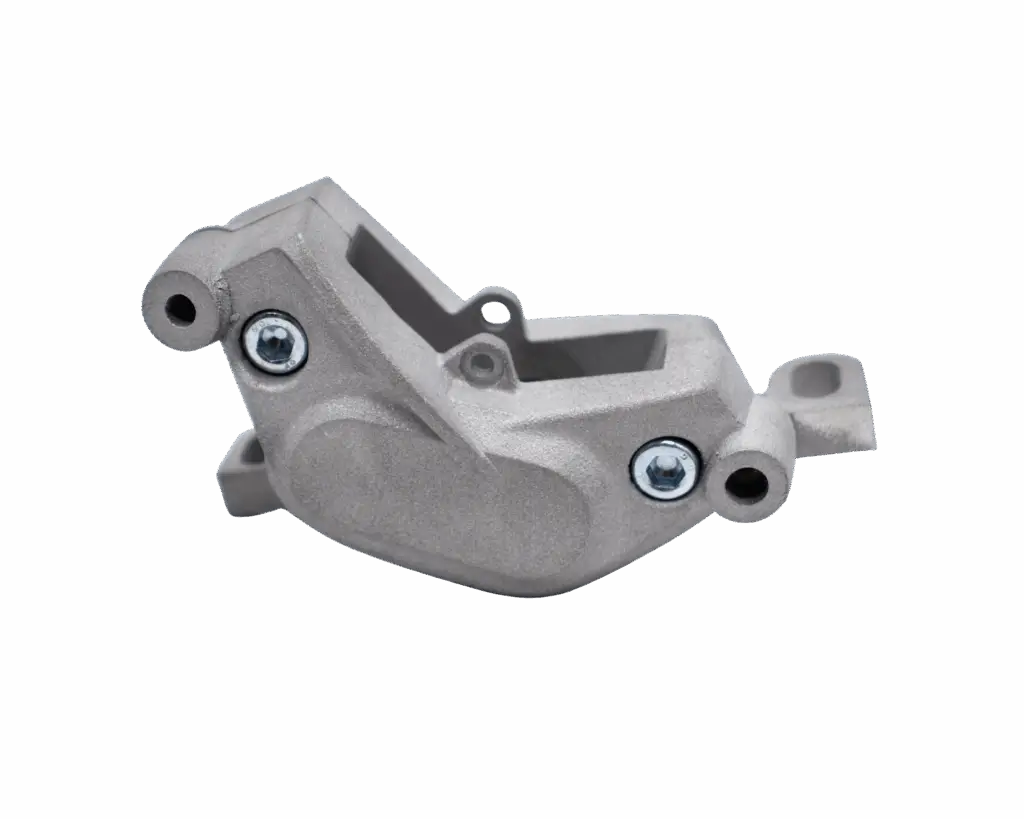

Aluminum

3.2382 / AlSi10Mg

The material AlSi10Mg is a high strength Aluminum alloy with age hardening properties. Apart from increasing the hardness of the material, the presence of Silicon also has a positive impact in the viscosity of the melt pool, making the alloy more processable than pure Aluminum in additive manufacturing. It is a common material in the aviation due to its excellent thermal conductivity, higher weight to strength ratio, good corrosion resistance and good processability. It is also often used in the casting industry as thin-walled components with good mechanical properties can be manufactured using this alloy.

Properties

- High dynamic load capacity

- Easily post processing possible

Applications

- Functional prototypes

- Motorsports

- Aerospace interior

- Mechanical engineering

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Aluminum

A6061-RAM2

A6061- RAM2, developed by Elementum3D, is an advanced aluminum alloy tailored for metal 3D printing applications. This material combines the well-known A6061 aluminum with a specialized reactive additive manufacturing (RAM) process, enhancing its printability and mechanical properties. Its unique composition reduces the warping and cracking issues typically associated with 3D printing standard aluminum alloys, allowing for precise, high-quality, and reliable prints, even in complex geometries. Apart from that, A6061- RAM2 has higher production speeds and better surface quality in comparison to the widely used AlSi10Mg alloy.

Properties

- Excellent strength-to-weight ratio

- Good corrosion resistance

- Improved thermal conductivity

Applications

- High performance industrial applications

- Aerospace

- Automotive applications

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Aluminum

Strength Al

Strength Al is an Al-Mg-Sc alloy developed for lightweight and high-performance applications where strength and weight are equally critical. The material offers excellent strength-to-weight ratio and printability, making it well-suited for motorsport, aerospace, automotive, structural, and robotics applications.

Properties

- High specific strength

- Very good strain values

- Light weighed

Applications

- High performance applications

- Weight optimized application

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Nickel Alloy

2.4668 / Ni718

The material 2.4668/Alloy 718 is a corrosion resistant high strength nickel-based super alloy. The presence of higher concentrations of Molybdenum and chromium the material exhibits excellent corrosion and oxidation resistance even at elevated temperatures. The material 2.4668 is heat treatable and this makes the material to be customized for various applications.

Properties

- Very good corrosion resistance at both high and low temperatures

- Good oxidation resistance up to 1000 °C with very good weldability and resistance to cracking

Applications

- Aviation and aerospace

- Oil and gas applications

- Defense

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Nickel Alloy

2.4856 / Ni625

Ni625 is a nickel-based superalloy known for its outstanding resistance to oxidation, corrosion, and thermal fatigue. It maintains its mechanical properties at temperatures up to 1000 °C and performs reliably in harsh environments such as seawater, acids, and chloride-containing media.

Typical applications include heat exchangers, exhaust components, fasteners, turbine parts, and chemical process equipment.

Properties

- High pitting-, cracking and stress cracking resistance

- Excellent resistance under a variety of oxidizing and reducing conditions

Applications

- Versatile applications

- Engine and power plant applications

- Chemical Industry

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Cobalt Chrome

2.4979 / CoCr28Mo6

The material CoF75, is a high strength, corrosion resistant cobalt-based alloy. The combination of Cobalt and Molybdenum increases wear resistance of the alloy. Apart from having excellent mechanical properties, the alloy is also bio compatible, making it ideal for implants and other medical applications. The alloy can also perform well at high temperatures without significant loss in the mechanical properties.

Properties

- Exceptional strength

- Good corrosion resistance

- High temperature resistance

Applications

- Medical implants

- Aerospace

- High-wear applications

Check powder prices

Find pricing information for the powder in our store.

Get suiting parameters

Find pricing information for the powder in our store.

Stay flexible with materials

Our Lab Module enables you to print with different materials without having to clean the whole system. Perfect for material development, research or prototyping.