Silencer (suppressor) manufacturing places extreme demands on materials, design precision, and thermal performance. Traditional manufacturing methods often limit internal geometries, require complex assembly steps, and slow down innovation cycles.

Metal additive manufacturing, specifically Laser Powder Bed Fusion (LPBF), is changing this landscape. By enabling the production of highly complex, monolithic metal parts, metal 3D printing allows suppressor manufacturers to improve performance, reduce production steps, and unlock entirely new design possibilities.

Why Metal 3D Printing Is a Game Changer for Suppressors

Suppressors are ideally suited for metal additive manufacturing. Their compact, cylindrical geometry and complex internal flow paths benefit directly from LPBF technology.

Key advantages include:

- Monolithic, near-net-shape production, eliminating assembly steps

- Advanced internal flow-through designs that reduce backpressure and heat buildup

- Optimized thermal management through complex internal geometries

- Minimal material waste compared to subtractive manufacturing

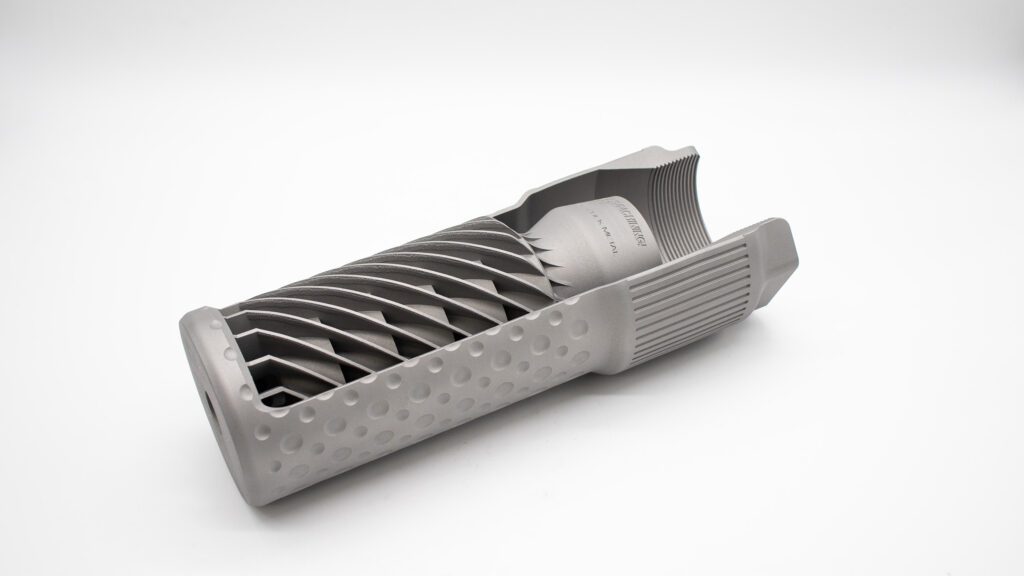

Unlike conventional baffle-based designs, metal 3D printing enables fluid-optimized internal structures that significantly improve suppression performance and durability

Conventional vs. Additive Manufacturing: A Shorter, Smarter Process Chain

Traditional suppressor manufacturing involves multiple sequential steps: CNC machining, tooling changes, post-processing, and assembly. Each step increases lead time, cost, and potential variability.

With metal additive manufacturing, the process chain is significantly simplified:

- No tooling or mold changes required

- No CAM programming for internal geometries

- No assembly needed for monolithic designs

- One consistent laser and parameter set throughout production

This streamlined workflow reduces complexity and enables faster, more flexible production — especially valuable for low to medium production volumes

The Additive Manufacturing Workflow with One Click Metal

Metal 3D printing of suppressors follows a clearly structured and efficient process chain.

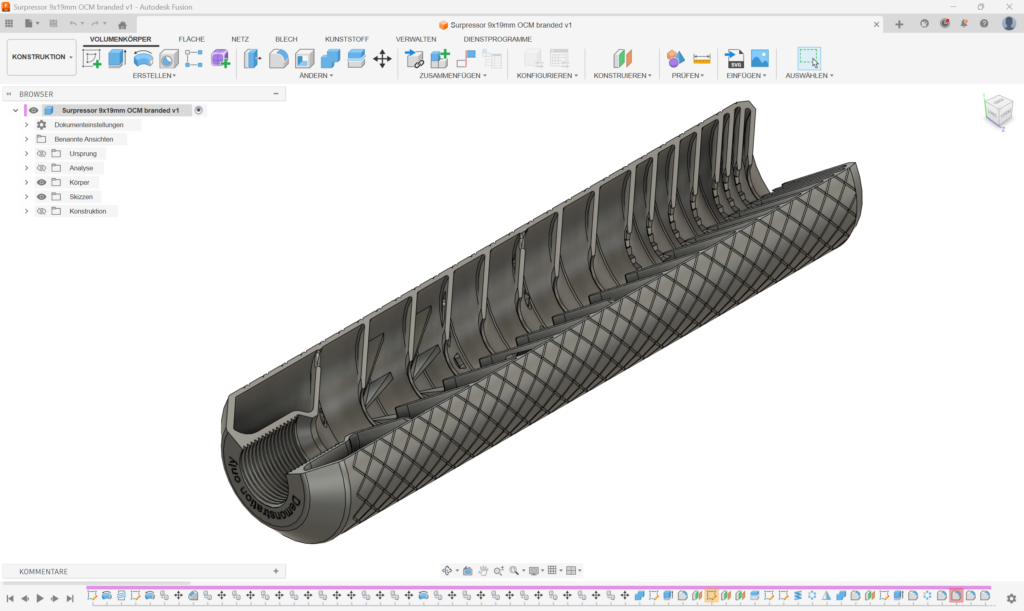

Step 1: CAD Design & DfAM

Suppressors are typically designed using parametric CAD models, allowing modular and adaptable geometries. By applying Design for Additive Manufacturing (DfAM) principles, designs are optimized for LPBF, ensuring manufacturability and performance from the start.

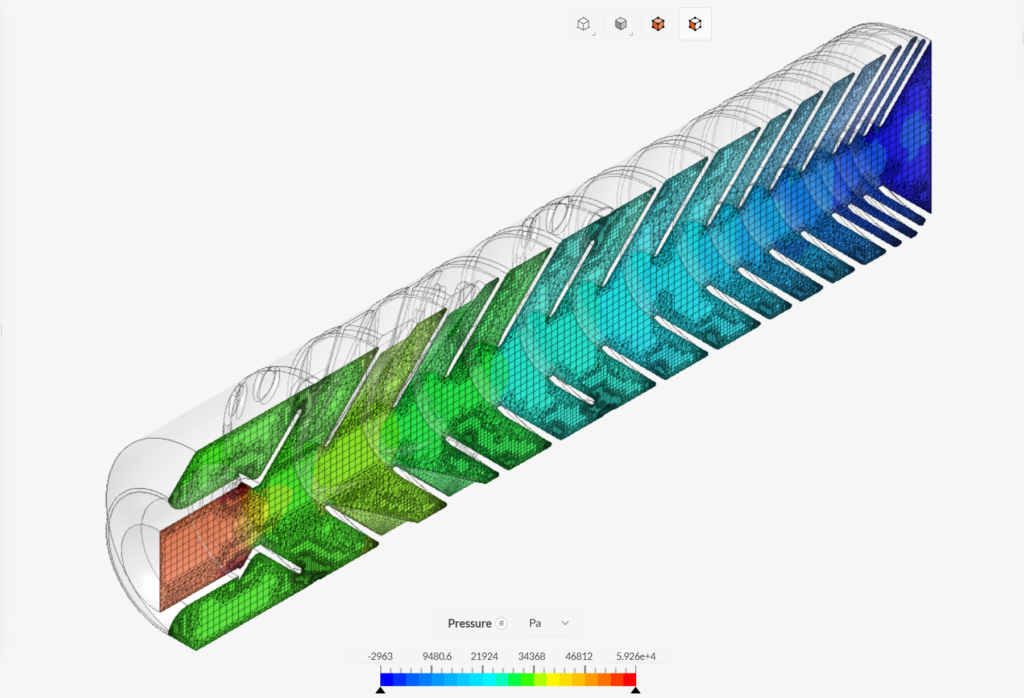

Step 2: Simulation

Advanced CFD simulations analyze internal gas flow, thermal behavior, and backpressure effects. These insights enable early optimization of baffle geometries and internal channels, reducing trial-and-error and accelerating development cycles.

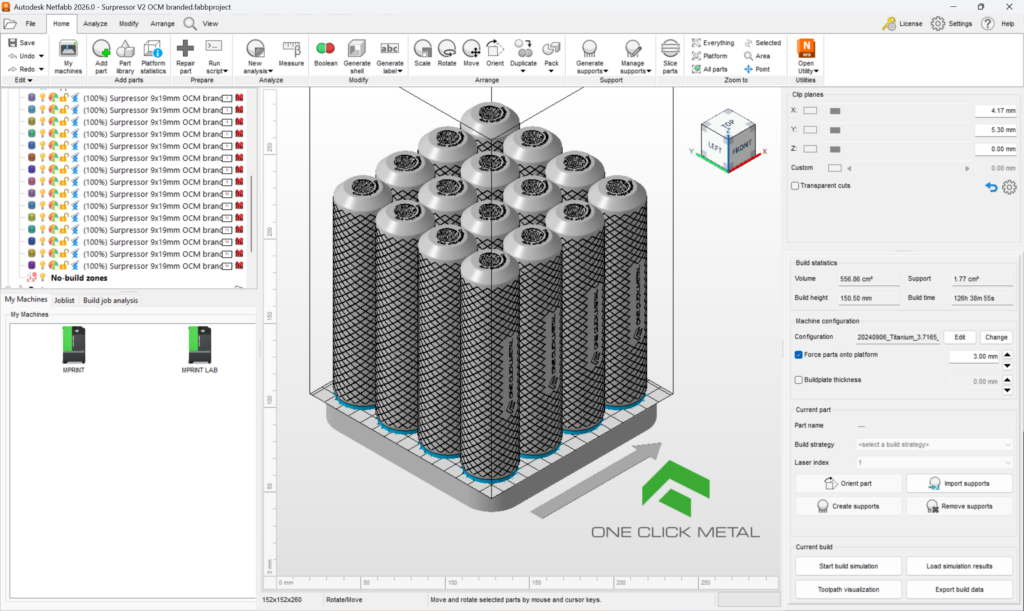

Step 3: Data Preparation & Job Setup

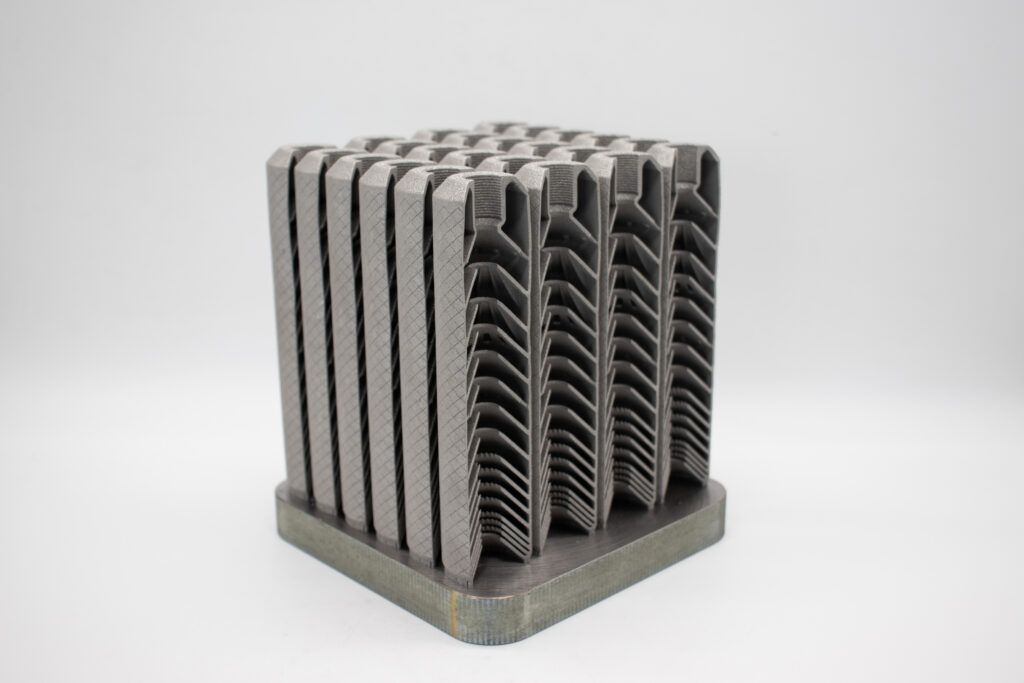

Parts are arranged and oriented within the build volume, support structures are generated, and process parameters are assigned. Thanks to their cylindrical form, suppressors use the available build space extremely efficiently, enabling high part density and cost-effective batch production.

Step 4: Printing, Unpacking & Sieving

Suppressors are printed on the metal 3D printer and subsequently unpacked and depowdered using a dedicated unpacking and sieving station. This integrated workflow ensures safe powder handling and consistent part quality

Design Freedom: Performance Without Compromise

One of the greatest strengths of metal 3D printing is unmatched design freedom.

LPBF enables the creation of:

- Complex lattice structures

- Integrated flow channels

- Fluid-optimized cores

- Internal geometries impossible to machine

This allows suppressor designers to precisely control gas flow, pressure, and heat distribution within a single, monolithic component. The result is higher suppression performance, improved reliability, and more efficient use of high-performance metal materials.

Scaling Suppressor Production with the PROline Metal 3D Printing System

For suppressor manufacturers looking to move beyond prototyping into robust serial production, One Click Metal’s PROline system offers an ideal production platform tailored to high-throughput and industrial applications. One Click Metal+1

The PROline line, centered around the MPRINTpro metal 3D printer and the MPUREpro unpacking & sieving station, is designed specifically for series production and larger part volumes — an excellent match for the demands of sound moderator manufacturing.

Flexible Production with Standard and Extended Build Modules

Metal 3D printing systems from One Click Metal offer flexibility for different suppressor sizes and production requirements.

- Standard Build Module: Efficient production of multiple suppressors up to 150 mm in height

- Extended Build Module: Enables printing up to 250 mm in height, ideal for longer suppressor designs

This modular approach allows manufacturers to adapt quickly to different product variants without changing tooling or infrastructure.

Sustainability and Manufacturing Efficiency

Beyond performance, LPBF also supports resource-efficient and sustainable production:

- Material is used only where needed

- Excess powder is fully recyclable

- Minimal waste and reduced post-processing

- Lower energy consumption compared to traditional manufacturing

Combined with on-demand production, metal 3D printing reduces inventory, storage requirements, and overproduction — supporting a more sustainable manufacturing strategy.

Proven in Practice: Customer Applications

Suppressors produced on One Click Metal systems are already in use by manufacturers such as MK Machining and Irregular Design Group.

Redefining Silencer Manufacturing

Metal 3D printing is redefining what is possible in silencer manufacturing. By enabling monolithic designs, advanced internal geometries, and efficient serial production, LPBF gives suppressor manufacturers a powerful competitive advantage.

With compact, user-friendly metal 3D printing systems, One Click Metal makes this technology accessible – allowing manufacturers to innovate faster, produce more efficiently, and deliver higher-performance suppressors.