What can metal 3D printing do?

The additive manufacturing process with metal powders offers a wide range of applications in a variety of different sectors and industries. For a first impression, we have listed various applications here.

Diverse and individual application possibilities

Where can you apply and successfully use metal 3D printing in your company? Depending on the branch and company, there is a wide range of possible applications for metal 3D printing.

Branches:

- Mechanical engineering

- Tool making

- Automotive

- Dental

- Medical

- Aerospace

- Jewelry

Possible applications:

- Product development

- Prototyping

- Industrial production of individual parts, small or large series

- Research and development

- Education

Miniseries production with the BOLDSERIES

Here we show you how to make a mini series production quickly and easily in six steps with the BOLDSERIES.

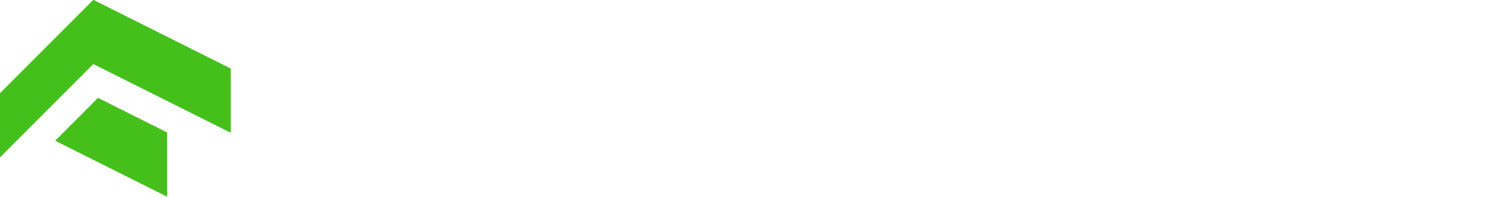

RNA Digital Solutions Tooling

Design by: RNA Digital Solutions & One Click Metal

Material: Stainless steel 1.4404

Advantages from additive manufacturing:

- Component combination: the number of components to be manufactured could be reduced by AM

- Individuality: many similar components can be easily adapted and manufactured

- Cost savings: reduced costs thanks to AM compared to milling production, which requires a lot of time and effort to manufacture the components

- Production time: the production time was reduced from six weeks to two days by AM

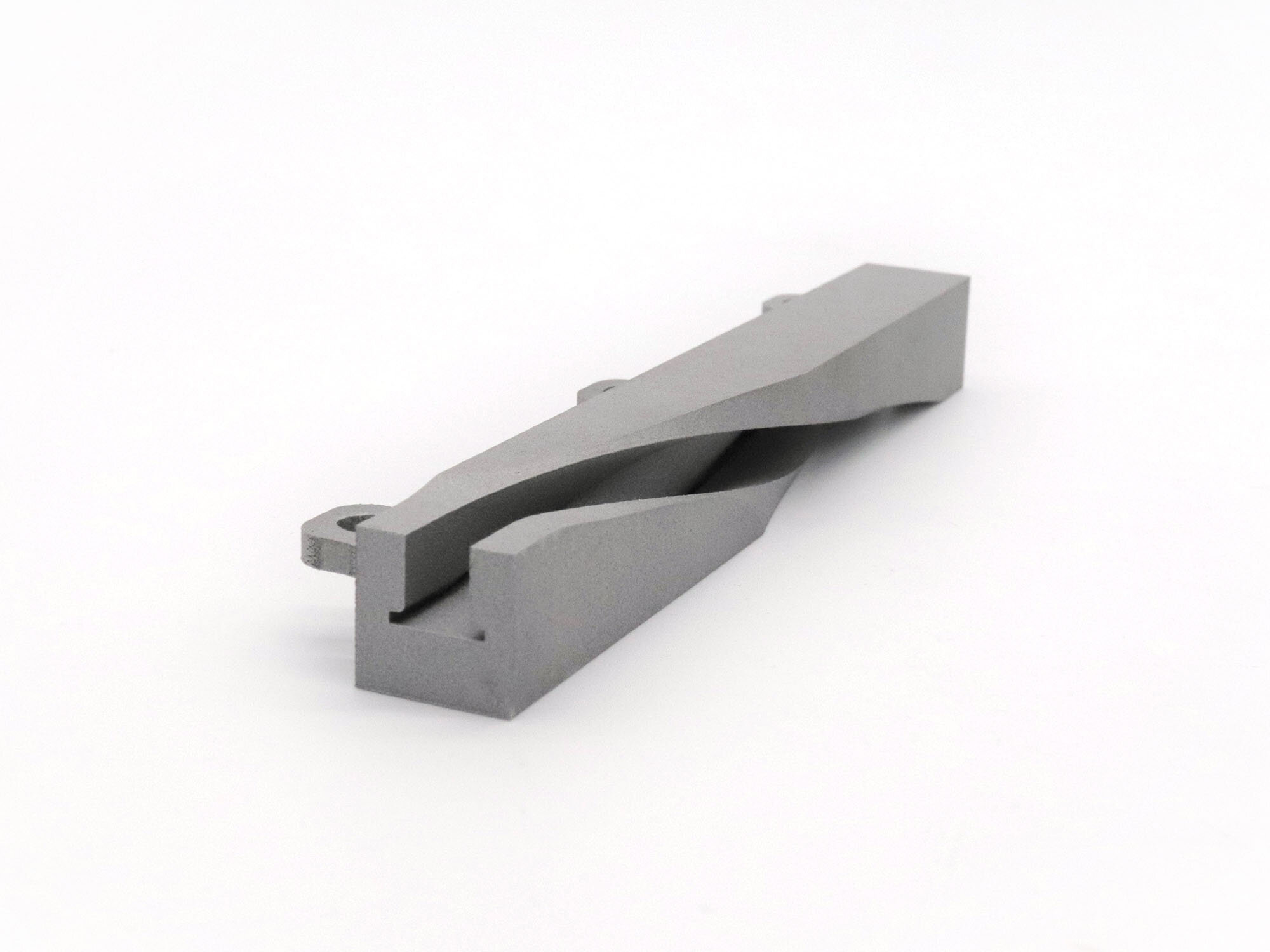

Valve and motor mounting bracket

Designed by: One Click Metal

Material: Stainless steel 1.4404

Advantages through additive manufacturing:

- Time and cost savings: Significant reduction of time and cost in terms of manufacturing time and cost as well as effort in terms of delivery and material.

- Accelerated development time: time independence through internal metal 3D printer provides flexibility and accelerates development time.

- Sustainable supply chain: in-house additive manufacturing provides transparent overview of value chain.

- Individual repeatability: simplified repeatability of a workpiece due to once defined parameter set. If necessary, changes can be easily adapted to the development status.

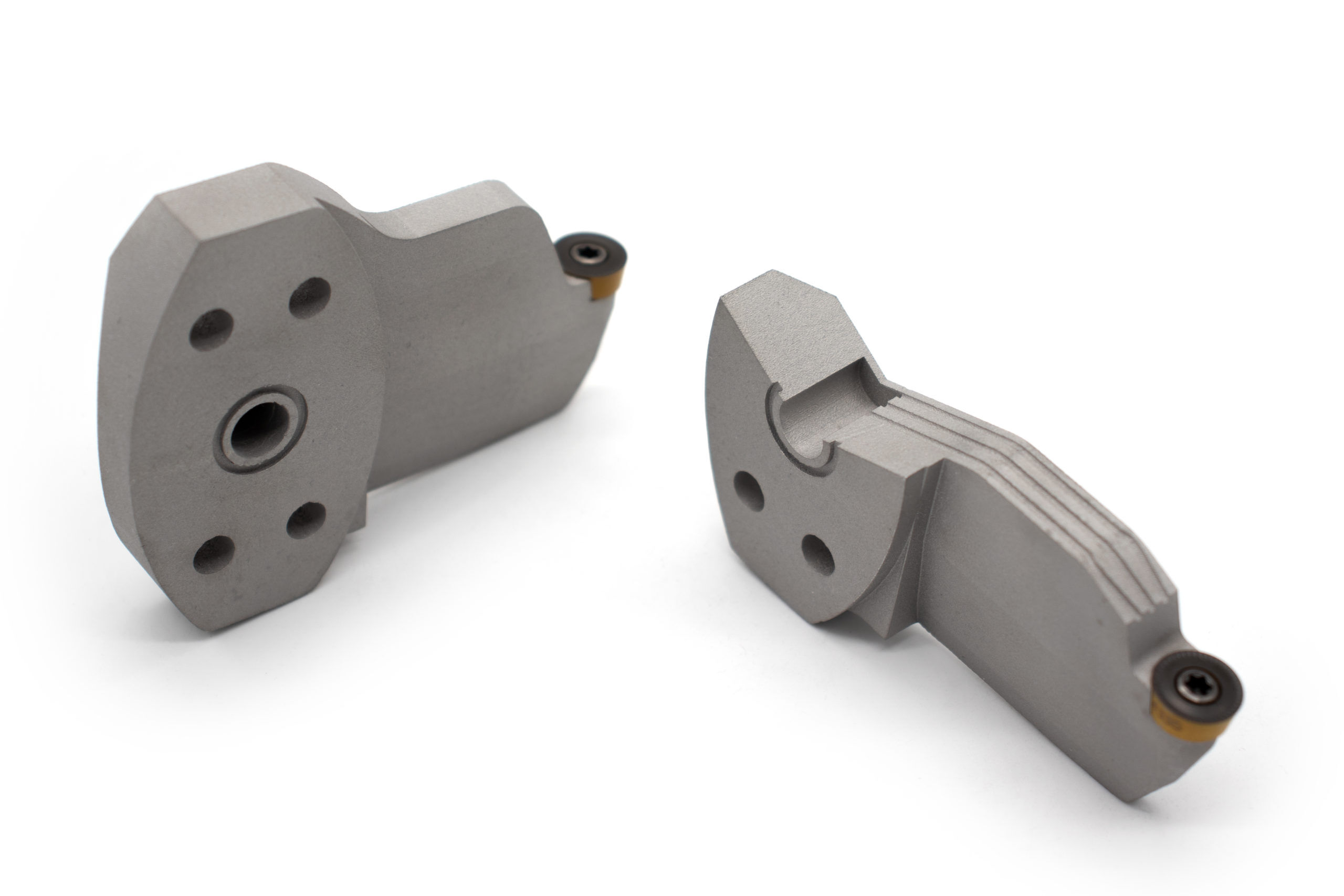

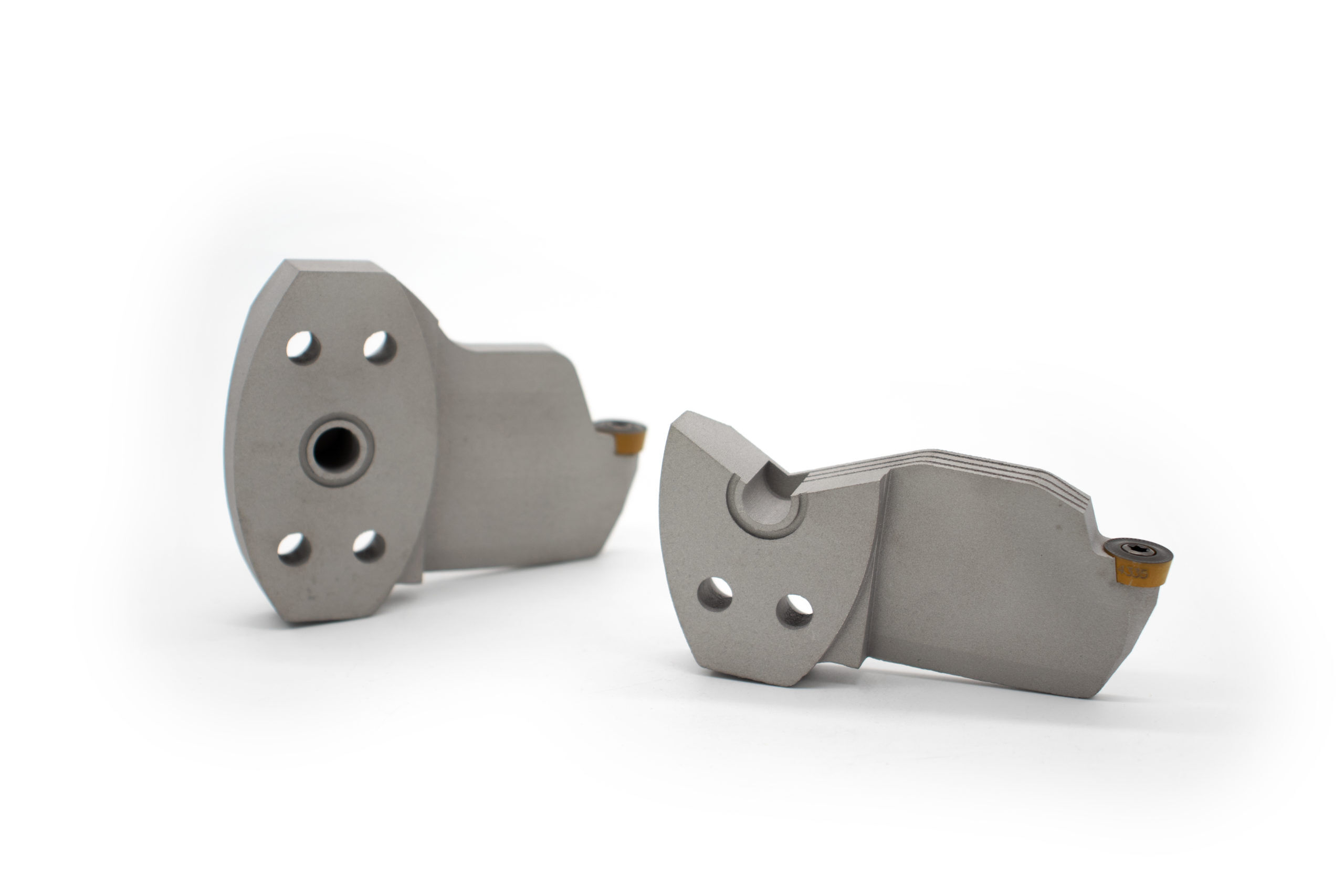

Tool holder

Designed by: One Click Metal

Material: Tool steel 1.2709

Advantages through additive manufacturing:

- Function integration: additive manufacturing significantly improves the fluid circulation through flow-optimised channels. This lowers the temperature at the cutting edge as well as at the workpiece. This enables longer tool life and better process stability.

- • Individuality: the cooling channels can be varied according to the application and optimally aligned to the cutting edge and cutting direction. In addition, if required, a significantly higher fluid pressure can be generated at the cutting edge through individually designable cooling channels – this helps to improve chip breaking and thus enables higher process stability, especially with long-chipping materials.