MPRINT

The 200W fiber laser allows great productivity and precision.

The cartridge system enables both safe and clean powder handling while minimising direct powder contact for the user.

With a build volume of 150mm x 150mm x 150mm, the MPRINT has the largest construction area in its performance range and is therefore very flexible.

With a focus diameter of 70µm and Galvo scanner, a wide field of applications opens to the user.

Due to the flexible extension with the lab module, the possibilities in the application for the LPBF technology grow.

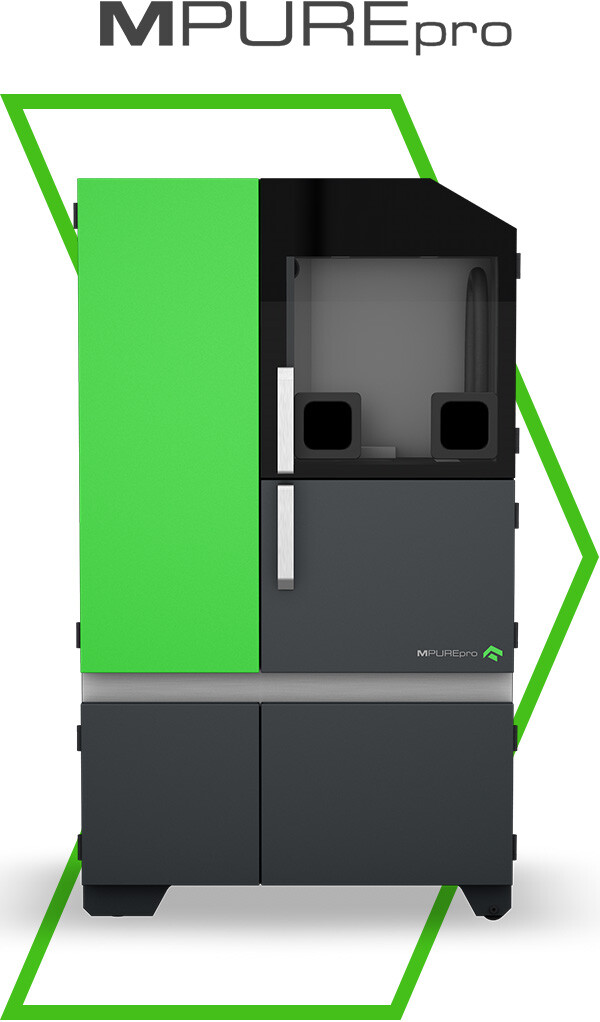

MPUREpro

One machine, two functions: with the MPUREpro, the unpacking of a component and the sieving of processed powder are combined in one machine. This means time and cost savings for the user.

The integrated ultrasonic sieve recycles processed powder. For this, a full overflow cartridge and an empty supply cartridge are inserted into the holders. The sieving then runs autonomously and independently of the user.

Unpacking a component with the MPUREpro is safe and easy for the user. Thanks to the chamber door as well as the gloves, the component is unpacked in a closed chamber. The integrated connection for an ATEX vacuum cleaner further simplifies unpacking.

Powder and cartridge system

The cartridge system of the BOLDSERIES ensures a safe and clean powder management.

- Separation of supply and overflow cartridges avoid risk of mix-ups.

- Direct powder contact for the user is significantly reduced.

- Most of the processed powder can be reused.

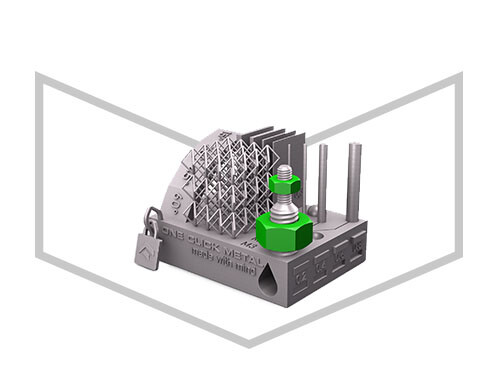

Application possibilities of metal 3D printing

The additive manufacturing process offers the user a wide range of applications, and value-added use cases can be generated almost anywhere.

Our systems are in operation in various industries as well as with different materials – and applicable for many more as well.

Look at our overview of materials and industries to get an idea of the variety of application areas.

MONE

MONE is our digital platform for location-independent monitoring and control of your MPRINT.

- Remote monitoring and control: Whether via PC, tablet or smartphone – with MONE you can monitor and control the current construction job regardless of location.

- Machine overview: Add machines, and you’ll see all available MPRINTs in the overview, which you can individually select.

- Print Progress: You have access to the built-in camera of the process chamber and can see the remaining time of the running build job.

- Powder Supply: Monitor the status of the powder supply and receive a forecast of when the cartridges need to be replaced.

- Upload of build jobs and job planning: Your next build jobs can be uploaded to the MPRINTs and planned through MONE.

Machine operation

The machine operation of MPRINT is easy to use and allows you to start a build job in just six steps.

- Select build job

- Prepare build module

- Check powder supply

- Check overflow powder

- Check machine

- Apply first layer

The machine operation guides you step by step through the individual phases of print preparation. In this way, you don’t forget a single step, you avoid mistakes, and you achieve fast results. The machine supports you from start to finish.

With our product solutions to a holistic process chain

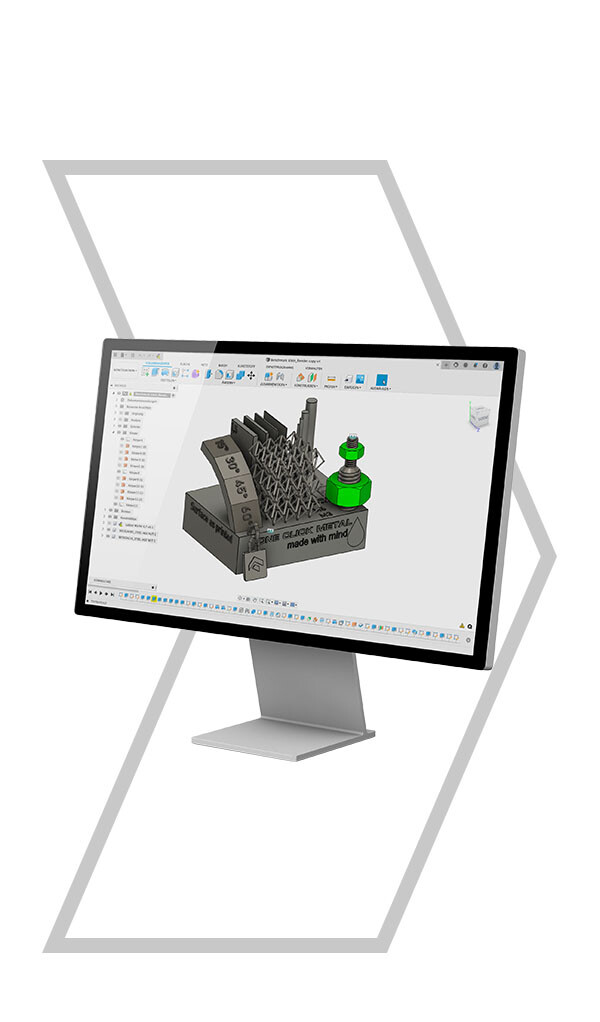

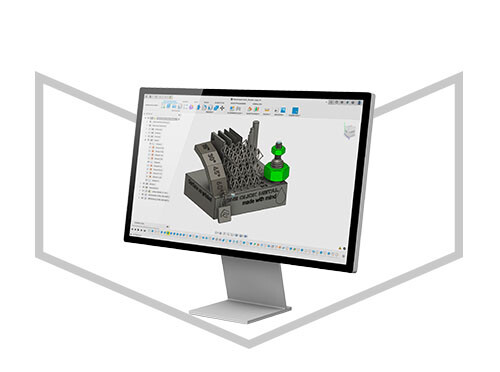

Data preparation

At the beginning there is your use case, for which you must create a component design in a CAD program. For this, you can use Autodesk Fusion 360, for example.

Job upload + Digital platform

Using MONE you can quickly and conveniently load your component onto the machine. MONE also allows you to keep track of the printing progress and powder supply of all your machines.

Printing process

After you have prepared the MPRINT for printing (see also the section machine operation), you can start the build job.

Unpacking process

Once the part is printed and the build module is inserted into the MPUREpro with the lifter, you can unpack it without direct powder contact and sieve processed powder at the same time.

Post processing

If your component has support structures, now is the time to remove them. Optionally, further finishing steps are possible, such as sandblasting, polishing, or grinding.

Your entry into metal 3D printing

Our product solutions are based on four approaches, which we have identified as the solution to our customers’ needs:

- The powder and cartridge system provides easy and safe powder management.

- The co-thinking-philosophy supports and guides the user from start to finish.

- The holistic product solution offers a perfectly harmonized system chain.

- A low financial entry barrier allows rapid access into AM-technology.

To make your entry into metal 3D printing as uncomplicated as possible, we have put together a complete package. It includes everything you need for a technology start – with transparent costs and an unbeatable price-performance ratio. We offer clear prices for clear performance.

Our total package includes:

- BOLDSERIES: MONE, MPRINT, MPUREpro

- Starter package with required basic equipment

- Powder package in three different sizes depending on powder requirements