The LPBF-process

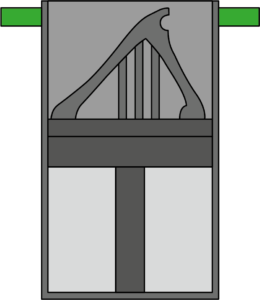

Laser powder bed fusion explained on the BOLDSERIES

The LPBF process

How does laser powder bed fusion work?

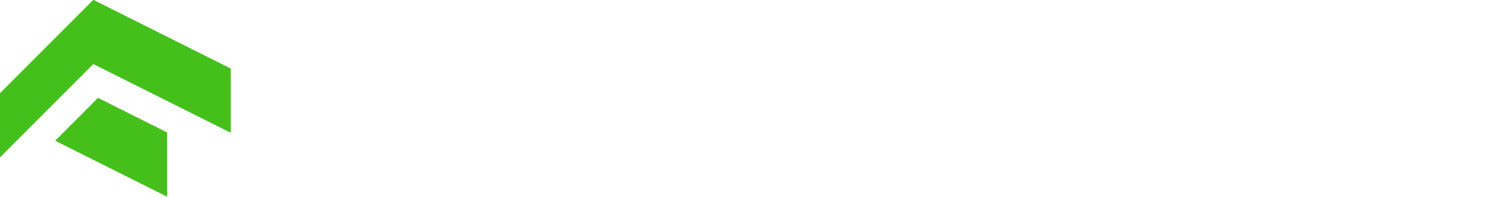

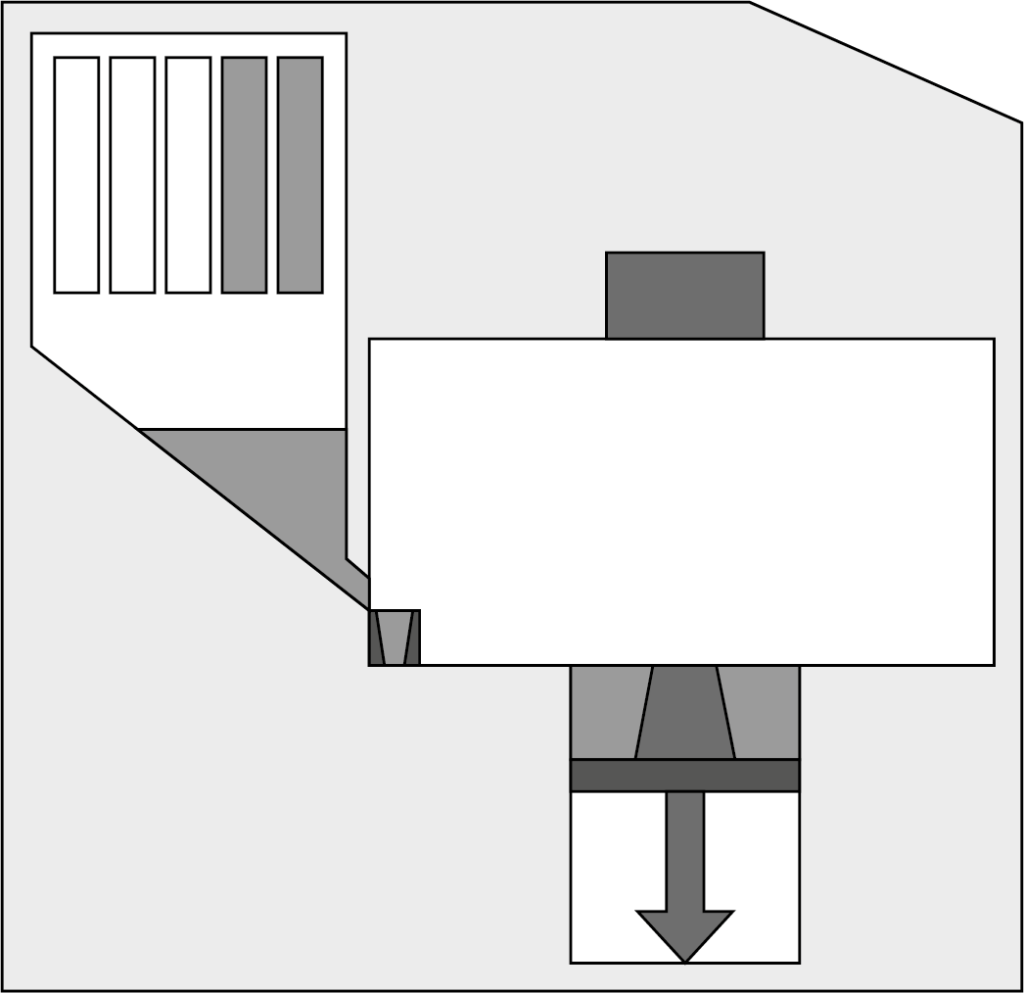

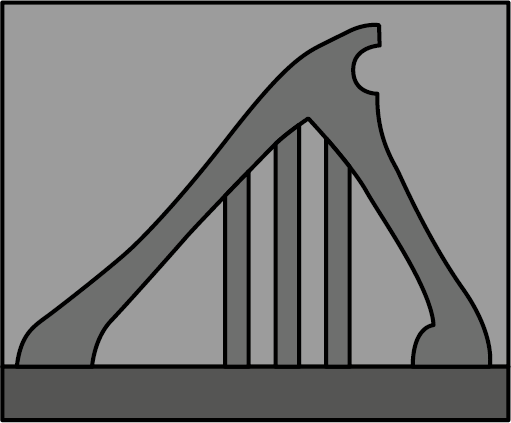

1. Powder supply

Powder supply using cartridges

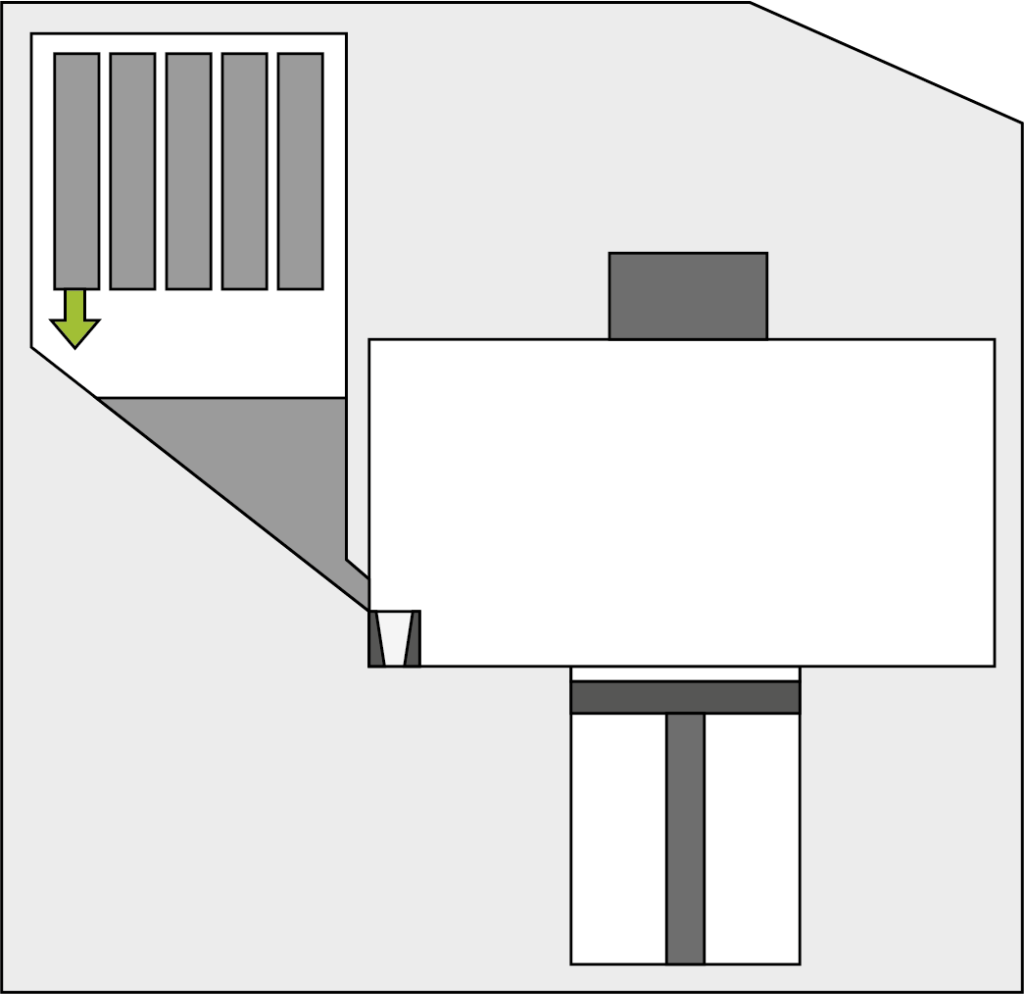

2. Coating

Powder deposition with coater

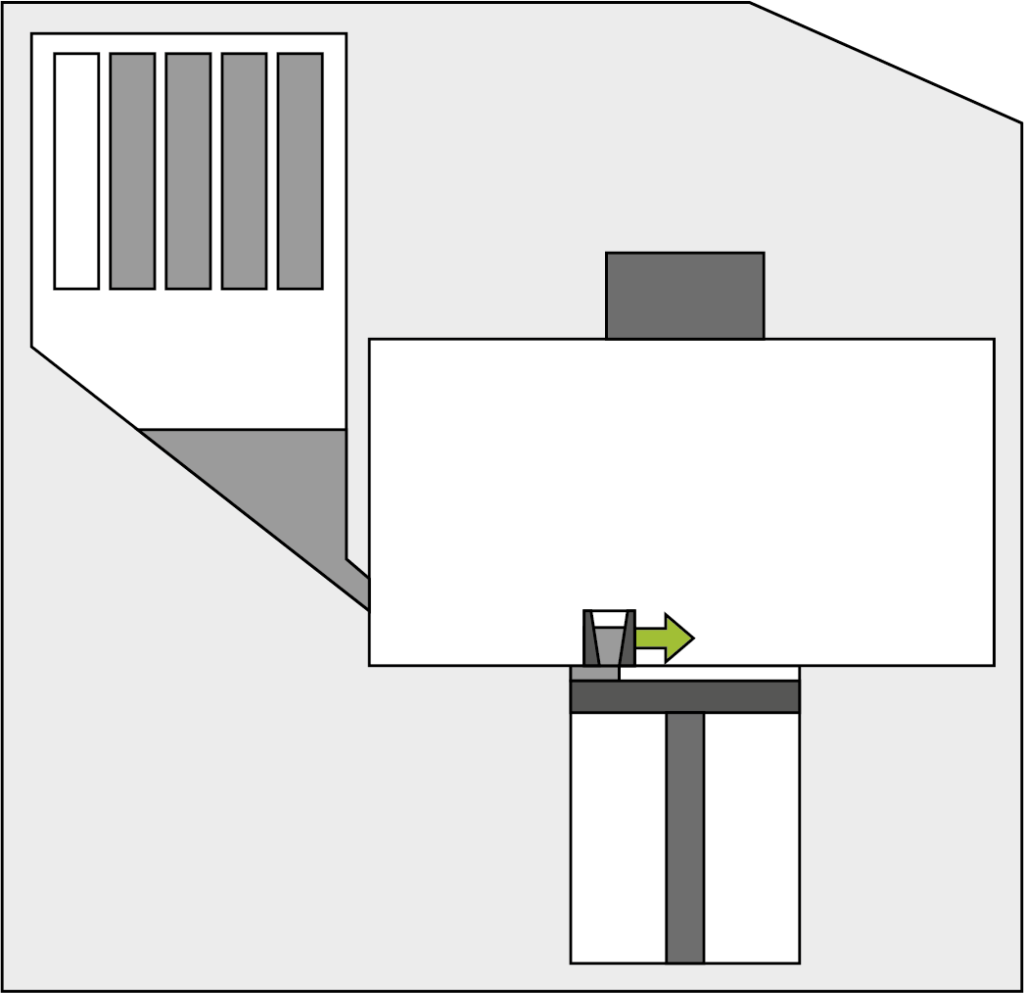

3. Fusing

Fusing process of the powder by the laser

4. Lowering

Lowering the building platform & repeat steps 1-4 until the component height is reached

1. Powder supply

Powder supply using cartridges

2. Coating

Powder deposition with coater

3. Fusing

Fusing process of the powder by the laser

4. Lowering

Decrease the building platform & repeat steps 1-4 until the component height is reached

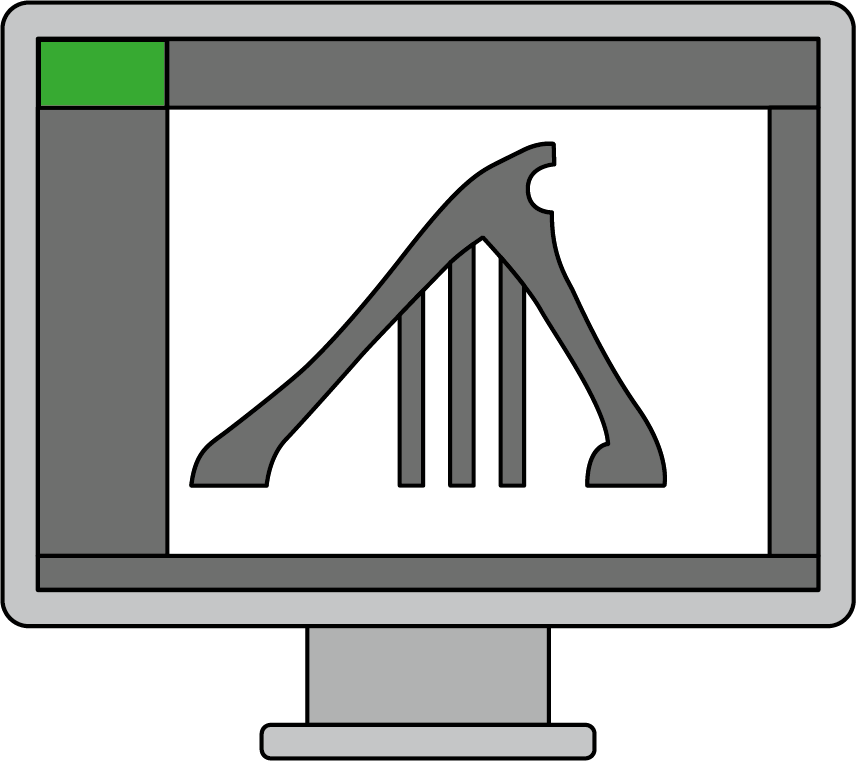

The process chain of metal 3D printing

We have summarized all steps from preparation to postprocessing for you here.

1. Data preparation

- CAD modelling: No component without a design template. For you, this means that you have to design the component in advance with a 3D optimised CAD software.

- STL export: Once you have finished designing, export your model.

2. Data preparation

- Preparation

- Supports generation: Most components require additional supports, e.g. for overhangs or certain angles. See also the support setting options in our MPREP software.

- Parameter selection: To ensure optimum printability of the components, we have developed material-specific parameter sets. Settings such as scan speed, laser power or track distance are matched to the properties of the print material to enable perfect interaction between powder and laser.

- Simulation

- Slicing and Preview

3. Print preparation

- Insert powder supply cartridges

- Insert build module

- (insert overflow cartridge)

- Load print job

- Inerting

4. Printing process

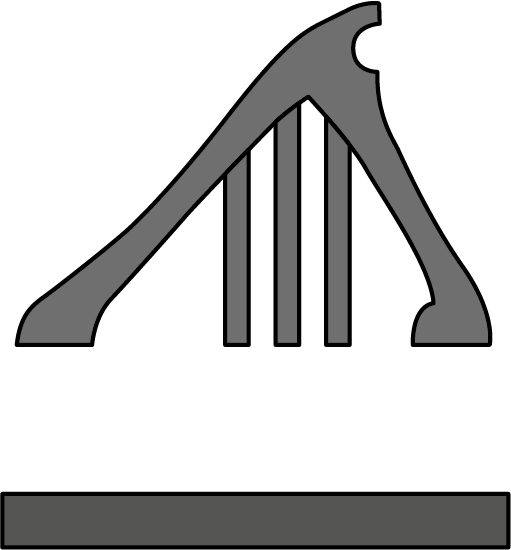

LPBF Process

- Powder supply

Powder supply using powder cartridges - Coating

Powder deposition by the coater - Fusing

Fusing process of the powder by the laser - Decreasing

Decrease the building platform & repeat steps 1-4 until the component height is reached

5. Unpacking process

- Take the construction module from MPRINT+ out and insert it into MPURE

- Rough powder removal using gloves

- Removing powder from interspaces and support structures

6. Separation of the component and the building platform

- Separation by band saw or spark erosion

7. Post-processing of the component

- Support removal

- Beams

- Surface treatment